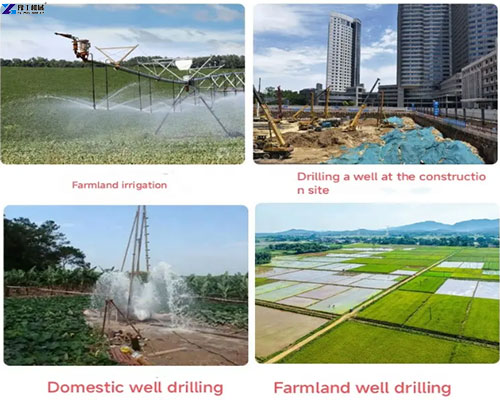

Water drilling equipment is specially used to drill water wells. YG’s well drilling rigs are powerful and have strong applicability. We mainly use this water well drilling rig for drilling water wells, monitoring wells, geothermal air conditioning holes, anchoring, foundation and bridge pile holes, etc. Our equipment can be matched into different forms of track drilling machines according to the different needs of customers. We are a professional drilling rig manufacturer, welcome to consult!

Water Drilling Equipment Parameters

| Model | YG-240-22P |

| Dimension | 1450*1550*1970mm |

| Weight | 200kg |

| Drill rod diameter | 42mm |

| Drill rod length | 1.5m/unit |

| Rod change method | Full automatic screw thread |

| Max drilling depth | 200m |

| Diesel engine power | 22HP |

| Drilling hole diameter | Within 280mm |

| Lifting height | 2.5m |

| Lifting force | 1000kg |

Best Water Well Drilling Rig Usage

People widely use the machine in industrial and agricultural water conservancy projects. It can drill rocks, monitoring wells, and exploration wells, and is particularly suitable for drilling geothermal heating holes. It can also meet the needs of projects such as engineering foundation reinforcement, loose gravel formation pipe drilling, and foundation drilling.

Great 6 Features of an Open Well Digging Machine

- Our water drilling equipment has imported optional high-torque hydraulic rotary power heads. This greatly saves equipment procurement costs and effectively improves construction efficiency.

- The loose layer can be drilled with a drill bit, mud and slag can be discharged, reverse circulation construction can be carried out, etc. The hydraulic support leg of the drilling rig has a large stroke. And we can transfer and load it without a crane.

- There is a thick protective sleeve to cover Each hydraulic oil pipe to extend the oil pipe service life.

- The overall performance of the well drilling rig is good, the operation is simple, and the maintenance and relocation are convenient.

- The machine has a large speed regulation range, which can meet the needs of various formations and various drilling rig functions.

- YG’s water well drilling rig can achieve hydraulic feed pressure and decompression drilling of the drilling tool through hydraulic control. When rotating we can raise and lower it, which is convenient for handling collapse in the hole and reducing accidents in the hole.

Structure of Track Drilling Machine

Water drilling equipment includes power equipment and drill bits, drill pipes, core tubes, drill racks, etc. It is generally divided into three categories: rotary rotary machine, impact drilling rig, and composite rotary machine.

Detailed Display of Water Well Drilling Rig

Working Principle of Water Drilling Equipment

Rotary water well-drilling rigs mainly rely on the rotation of the drilling tool to break the rock formation into holes. Generally, there are large and small pot cone drilling rigs, positive and negative circulation rotary drilling rigs, hydraulic power head drilling rigs, and downhole vibration rotary drilling rigs. Simple rotary drilling rigs only have drilling devices, and well-structured rotary drilling rigs have two parts: drilling devices and circulating well cleaning devices. The drilling tools of rotary track drilling machines include drill pipes and drill bits. The nominal diameters of commonly used drill pipes are 60, 73, 76, 89, 102, and 114 mm. Drill bits are divided into two categories: full drill bits and ring drill bits.

Repair and Maintenance of Track Drilling Machine

- Wipe the outer surface of the drilling rig clean, and pay attention to the cleanliness and good lubrication of the surfaces of the drilling rig base slide, vertical shaft, etc.

- Check whether all exposed bolts, nuts, safety pins, etc. are firm and reliable.

- Add lubricating oil or grease according to lubrication requirements.

- Check the oil level position of the gearbox, transfer case, and hydraulic system oil tank.

- Check for oil leaks everywhere and deal with them as appropriate.

- Eliminate other faults occurring within this class.

YG is a high-quality construction machinery manufacturer. We can provide you with a variety of drilling equipment, and water well drilling rigs are one of the household well drilling equipment. We also produce DHT boring machines, rotary drilling rigs, trailer-type water well-drilling rigs, core drilling rigs, solar pile drivers, mud pumps, and other equipment. Contact us to get the factory price of the water well drilling rig you need!