Stone wire saw is a widely used equipment in the field of mining. As a multifunctional cutting and demolition tool, a diamond wire saw is not only suitable for mining and rough material mining. But also flexibly handle the cutting needs of curved plates, large slabs of stone, thick concrete, concrete reinforcement of complex structures, and even bridges and roads. It is easy to install and flexible to use. Whether it is horizontal or vertical cutting, it can be done with ease. YG wire saw adopts advanced technology, which not only greatly improves the safety and efficiency of mining operations, but also shows a very high cost-effectiveness. Please contact us for more product information!

Stone Wire Saw Technical Parameters

| Model | YG37B | YG45B | YG55B | YG75B | YG55C | YG75C | YG110C | YG15E | YG22E | YG30E | YG37E | YG11X |

| Main Motor | 37KW | 45KW | 55KW | 75KW | 55KW | 75KW | 110KW | 15KW | 22KW | 30KW | 37KW | 11KW |

| Flywheel’s Diameter | 0.75KW | 0.75KW+0.37KW | 0.37KW | 0.75KW | 0.75KW | / | ||||||

| Guide Pulley’s Diameter | Marble Φ800Granite Φ600 | Marble Φ900Granite Φ800 | Φ600 | Marble Φ800Granite Φ600 | Φ5800 | |||||||

| Wire Speed | 2XΦ380 | 2XΦ300 | 2XΦ380 | Φ300 | ||||||||

| Walking Speed | 0-160m/h | 0-30m/h | ||||||||||

| Rotation Angle | 360 Electric | 360 Hand Control | ||||||||||

| Max Wire Length(m) | 60 | 80 | 100 | 120 | 80 | 100 | 120 | 20 | 30 | 50 | 60 | 10 |

| Net Weight(kg) | 1950 | 2030 | 2780 | 2980 | 2980 | 3120 | 3785 | 1050 | 1090 | 1440 | 1650 | 345 |

Application of Diamond Wire Saw

The application of stone wire saw is mainly aimed at cutting rocks of various materials, such as granite, marble, sandstone, limestone, etc. The specific applications are as follows:

- Cutting large rock structures: Diamond wire saws can handle large rock structures such as walls, beams columns, etc., providing efficient cutting solutions for preparation before blasting or direct mining.

- Precision cutting of stone mining: In stone mining operations, diamond wire saws have become a key tool that can accurately cut marble, granite, limestone, and other stones into ideal sizes and shapes for transportation and subsequent processing, helping to optimize the entire mining process.

- Efficient separation of ore and surrounding rock: In order to achieve effective extraction and processing of ore, diamond wire saws are widely used to separate the connection between ore and its surrounding rocks. This process not only improves the purity of the ore but also speeds up the extraction speed.

- Environmental restoration after mining: When the mining task is completed, the stone wire saw is used to cut and remove the remaining rock blocks. This helps to restore the natural ecology and landscape of the mining area.

The wide application of diamond wire saws in the field of mining is due to their high efficiency, precision, and durability. These characteristics directly promote the improvement of mining efficiency and the reduction of costs. However, safety regulations must be strictly observed during operation to ensure the personal safety of staff and the stable operation of equipment.

Wire Saw Machine for Granite Structure

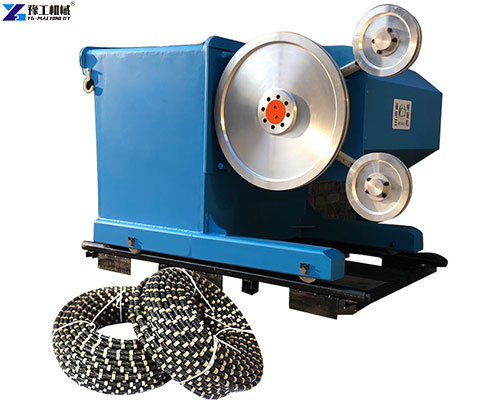

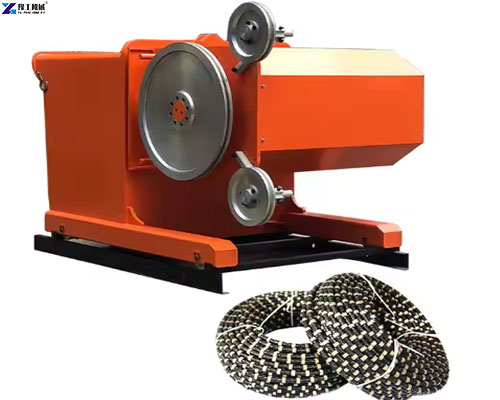

Stone wire saws are generally composed of power mechanisms, walking mechanisms, and control systems.

- The power mechanism is the mechanism that drives the active rope wheel to rotate. There are mainly motors and reducers.

- The function of the walking mechanism is to drive the active rope wheel to reciprocate on the working guide rail and maintain the tension of the diamond rope during the sawing process.

- The control system monitors and controls the speed of the active rope wheel, the tension of the diamond rope, and the movement speed of the walking mechanism.

Working Principle of Stone Wire Saw

The working principle of a mining wire saw is to grind and cut materials by the hardness and sharpness of diamond particles under the drive of the electric power device. When the wire saw passes through the material, the diamond particles will grind and wear the surface of the material, thereby achieving the purpose of cutting. The wire saw can be cut by pulling, circulating, or reciprocating motion.

5 Advantages of Diamond Wire Saw

- Wide adaptability. Diamond wire saws are suitable for almost all types of mines and can handle various rocks.

- Powerful and efficient. The mining depth of the mine rope saw is deep, which can reach 10-20m or even deeper. Secondly, the cutting speed is fast, which can generally reach 3-4m2/h.

- It can be cut from various directions. The rope saw can cut vertically, horizontally, beveled, and in other directions, and can also perform blind cutting.

- High yield rate and low comprehensive cost. First of all, the cut surface of the rope saw is very flat and will not cause any internal damage to the rough material. Secondly, the sawing seam is small, only about 11mm, which will not cause a waste of resources.

- Safe and environmentally friendly, rope saw mining is noiseless and dustless. Therefore, it will not affect nearby residents and other working surfaces, and it has a high degree of automation and separate control, low labor intensity, and high safety for workers.

Diamond Rope Saw Installation

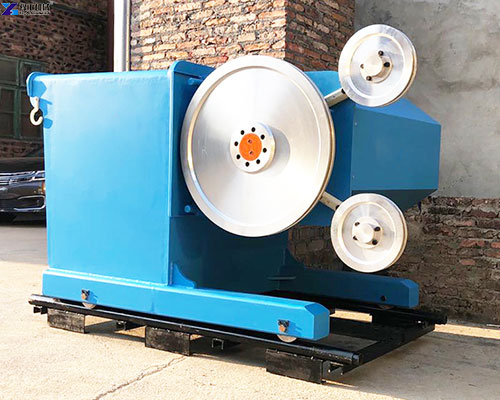

- Install the guide rail at the appropriate position at the front end of the surface to be cut.

- Lift the stone wire saw onto the guide rail. Before lifting, carefully check whether each connection part is firm. Balance must be maintained during the lifting process to ensure safety.

- After the wire saw is installed on the guide rail, place the operating table at a suitable position behind the wire saw so that the operator can clearly observe the operation of the wire saw.

- After the machine is installed, connect the main cable and control cable reliably and firmly.

Maintenance and Care of Diamond Stone Wire Saw

- Check the cable frequently. If it is damaged, it must be wrapped or replaced immediately to prevent leakage.

- Clean the moisture and dust on the electric control box, machine body, and operating table regularly to keep the equipment clean.

- Keep the inside of the control box dry. If it is idle for a long time, it should be dried before reuse.

- Check whether the heat dissipation cover of the main motor is normal before starting the machine to prevent affecting the heat dissipation of the main motor.

- When sawing, pay attention to the waterproofing of the heat dissipation port of the main motor to prevent cooling water from entering the main motor through the heat dissipation port and causing a short circuit.

- The operator must add lubricating oil to each lubrication point of the equipment every day.

- Clean the guide rails and the middle feed rollers frequently and apply grease to prevent rust.

- Be careful when moving the operating table and do not pull the cables forcibly. The operating table should be placed in a rainproof place.

Recommended Equipment from YG

Rope saws are cutting equipment used in many fields. YG is a professional manufacturer of cutting and breaking equipment. It also produces hydraulic rope saws, electric wire saws, high-frequency wire saws, crawler electric rope saws; hydraulic wall saws, high-frequency wall saws, rock splitters, wood log crushers, rock splitters, and other equipment. Until now, our rope saws have been exported to Australia, Singapore, Saudi Arabia, Brunei, Israel, Brazil, Madagascar, the Philippines, India, the United States, and so on. Welcome to consult us at any time!