A steel hoop bending machine is also called a rod and flat bar bender. It can change the shape of the rebar. It can process the rebar into specified angles and models. YG produces different types of rebar bending machines. We will recommend the corresponding machine model according to the diameter and shape of the rebar you need to process. Our rebar bending machine is efficient, precise, and easy to operate. In addition, we can also produce more intelligent CNC hoop bending machines, rebar straightening and cutting machines, rebar cutting machines, rebar upsetting machines, rebar thread rolling machines, and other rebar processing equipment. Welcome to buy our rebar processing equipment!

Rod and Flat Bar Bender Parameters

| Model | Technical Parameter | |

| YG-20/YG-20D | Motor Power(kW) | 2.2 |

| Rebar Diameter(mm) | 4-16 | |

| Round Bar Diameter(mm) | 4-20 | |

| Weight(kg) | 100 | |

| Dimension(mm) | 800*500*730 | |

| YG-25/YG-25D | Motor Power(kW) | 3 |

| Rebar Diameter(mm) | 4-22 | |

| Round Bar Diameter(mm) | 4-25 | |

| Weight(kg) | 140 | |

| Dimension(mm) | 850*550*760 | |

| YG-28/YG-28D | Motor Power(kW) | 3 |

| Rebar Diameter(mm) | 4-25 | |

| Round Bar Diameter(mm) | 4-28 | |

| Weight(kg) | 170 | |

| Dimension(mm) | 900*600*860 | |

| YG-32/YG-32D | Motor Power(kW) | 3 |

| Rebar Diameter(mm) | 4-28 | |

| Round Bar Diameter(mm) | 4-32 | |

| Weight(kg) | 180 | |

| Dimension(mm) | 750*750*800 | |

| YG-28S | Motor Power(kW) | 3 |

| Rebar Diameter(mm) | 4-25 | |

| Round Bar Diameter(mm) | 4-28 | |

| Weight(kg) | 170 | |

| Dimension(mm) | 900*600*860 | |

| YG-20H hydraulic rebar cutting machine | Motor Power(kW) | 3 |

| Rebar Diameter(mm) | 6-20 | |

| Round Bar Diameter(mm) | 6-20 | |

| Weight(kg) | 180 | |

| Dimension(mm) | 750*570*750 | |

| YG-32S | Motor Power(kW) | 3 |

| Rebar Diameter(mm) | 4-28 | |

| Round Bar Diameter(mm) | 4-32 | |

| Weight(kg) | 200 | |

| Dimension(mm) | 900*850*800 | |

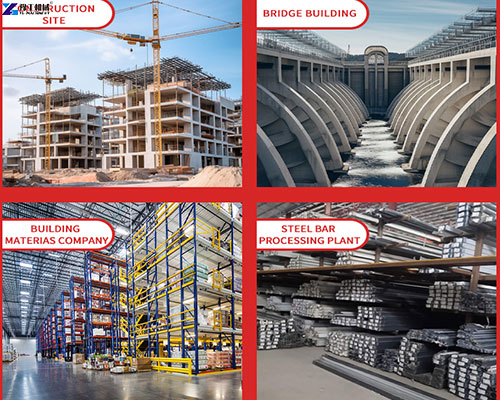

Application of Rod And Flat Bar Bender

- Steel hoop bending machine is widely used in various large-scale infrastructure construction such as construction projects, high-speed railways, highways, bridges and tunnels, subways, and urban rails.

- And rebar processing and distribution centers and other fields. These centers provide standardized semi-finished rebar products for construction sites, and rebar bending machines are one of the indispensable processing equipment.

- Prefabricated component production. In prefabricated buildings, a large number of prefabricated components such as beams, columns, wall panels, etc. are required. These require pre-processing of the rebar skeleton. The steel bar bending machine can quickly and accurately help users bend steel bars into the desired shape, improving the production efficiency and quality of prefabricated components.

6 Features of Rebar Bending Machines for Sale

- Stable operation. The steel hoop bending machine has the characteristics of low equipment failure rate, stable operation, and long service life.

- Simple operation. The equipment only needs one person to operate, so it also saves a lot of manpower and saves labor costs for the factory. Suitable for large-scale steel bar processing bending factories.

- High work efficiency. The working efficiency of the steel bar bending machine is 4-5 times that of manual bending, and it can produce about 5 tons per day.

- Standardized work. Precise bending work is suitable for large-scale and factory operations.

- Wide range of steel bars. It has a wide range of angle adjustments and can bend square, trapezoidal stirrups U-shaped hooks, and other types of steel bars.

- Save raw materials. The steel bar bending machine continuously processes steel bars with almost no loss of steel bar head.

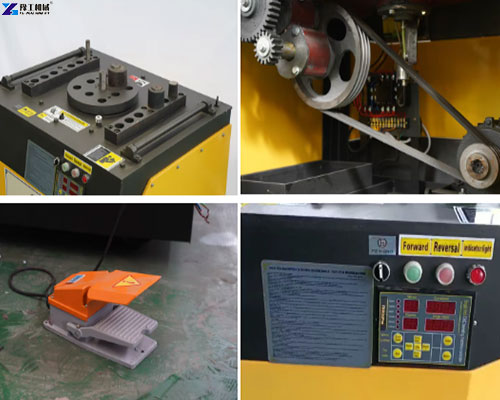

Working Principle of Steel Bar Bending Machine

When working, the motor drives the working disk to rotate through a series of transmission devices. Then, by exchanging the matching gears, the working disk can get different speeds. This can adapt to bending steel bars of different diameters. The steel bars are bent into the required shape under the rotation of the working disc.

Automatic Rebar Bender Machines from YG

Yugong is a professional manufacturer of steel hoop bending machines. We have high-precision and high-efficiency machining centers and CNC machine tools. As well as advanced automated production lines and testing equipment. This equipment not only improves production efficiency and product quality but also greatly reduces labor costs. Therefore, we have a strong production capacity and can provide you with multiple steel bar hoop bending machines at a preferential price. At present, we have exported steel bar hoop bending machines to UAE, Brazil, Bolivia, Chile, Colombia, Ecuador, Peru, Malaysia, Indonesia, the Philippines, Russia, the United Arab Emirates, and many other countries. And have long provided customers with other steel bar processing equipment. We also provide rebar rust removal machines, rebar sleeves, rebar cold extrusion machines, chain link fence machines, barbed wire machines, etc. If you need to, please contact us, and we look forward to cooperating with you!