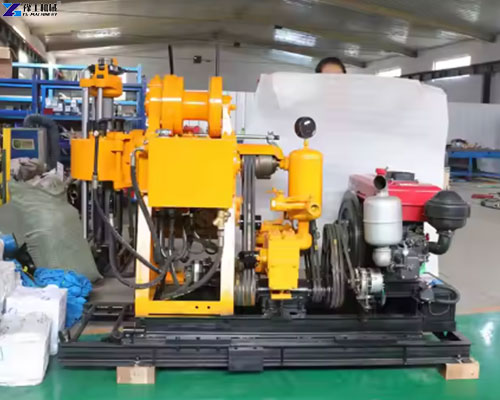

The spindle drilling rig belongs to core drilling equipment. This series of drilling rigs are medium-depth spindle core drilling rigs. We mainly apply this equipment in the fields of engineering geological survey, hydrogeological survey, exploration of oil and gas fields, and water well drilling. The equipment has the characteristics of compact structure, small volume, light weight, easy disassembly, flexible and reliable operation, etc. YG offers core drilling rigs that can meet various drilling processes. YG supports customized services. Click to get the price of the core drilling rig!

Spindle Drilling Rig Parameters

| Technical Parameter | Model | XY-3 |

| Drilling Depth (m) | 600 | |

| Open Hole Diameter (mm) | 325 | |

| Final Hole Diameter(mm) | 75 | |

| Drill Pipe Diameter(mm) | 60 | |

| Drill Pipe Inclination (°) | 90-75 | |

| Power (kW) | 13.2 | |

| Weight (kg) | 1800 | |

| Dimensions(mm) | 2600*900*1750 | |

| Spindle | Speed(r/min) | 32-1057 |

| Stroke(mm) | 600 | |

| Winch | Max Pull Force(kg) | 3000 |

| Pull Speed(m/min) | 0.3-1.9 | |

| Rope Diameter(mm) | 12.5 | |

| Roll Capacity(m) | 65 | |

| Drill Mast | Rated Load(ton) | 18 |

| Height(m) | 11 | |

| Mud Pump | Mud Pump | BW-250 |

| Work Pressure | 80kg/cm² | |

| Displacement(L/min) | 250 | |

| Hose | Inlet Hose Diameter(mm) | 71 |

| Outlet Hose Diameter(mm) | 51 |

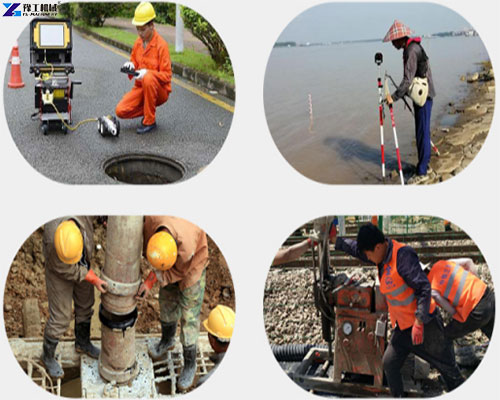

Application of Hydraulic Core Drilling Machine

Spindle drilling rigs are mainly applied to geology, metallurgy, coal, hydrology, engineering, and other industries. And we can also use it in engineering geological exploration, mine pit ventilation, drainage, and other engineering drilling construction. Specific working scenes are water well drilling, prospecting, surveying, piling, medium and shallow hole exploration, anchor cable, grouting, engineering construction, etc.

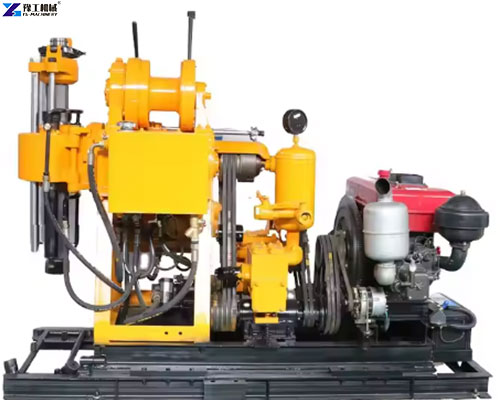

7 Features of Core Drill Rig for Sale

- The spindle core drill rig adopts an automobile gearbox assembly, with multiple speed grades and a reasonable speed adjustment range.

- The whole machine has large torque and strong bearing capacity. It can be manipulated to change the speed from a distance, and the operation is centralized and convenient.

- Large installed power, with 2 reverse speeds, easy to deal with accidents.

- The spindle drilling rig has a centralized operation handle, a reasonable and compact layout, easy operation, flexibility, and reliability.

- The machine also has a normally closed hydraulic chuck, which is convenient and flexible to maneuver.

- We can realize vertical shaft operation on this equipment.

- The diameter of the through hole of the vertical shaft is large. And we can replace it with large hexagonal active drilling rods.

Hydraulic Drilling Rig Provided by YG

Founded in 2006, YG Machinery Co., Ltd. has several engineers engaged in geological drilling machinery manufacturing and processing and drilling rig design. Since its establishment until now, we have been committed to developing more powerful and convenient spindle drilling rigs and water well drilling rigs. This series of core drilling rigs are easy to transport, easy to walk, easy to operate, and versatile. Therefore we mostly use it in the fields of hydrology, geology, exploration, hydraulics, and water wells. This series of core drilling rigs can be in various forms, such as trailer mounted water well drilling rigs, tractor mounted water well drilling rigs, crawler drilling rigs, etc.

Diamond Drilling Equipment Market

Nowadays, due to the good quality and high reputation of the core drilling rig. We have been exported to Indonesia, Mexico, Bulgaria, Cameroon, USA, Ecuador, Argentina, Australia, Togo, Philippines, Chile, Philippines, and other countries. We can also provide you with hydraulic wire saws, electric wall saws, fully hydraulic core drilling rigs, rotary drilling rigs, piling drivers, wood splitters, wood crushers, and other equipment. Click to get machines at competitive prices!