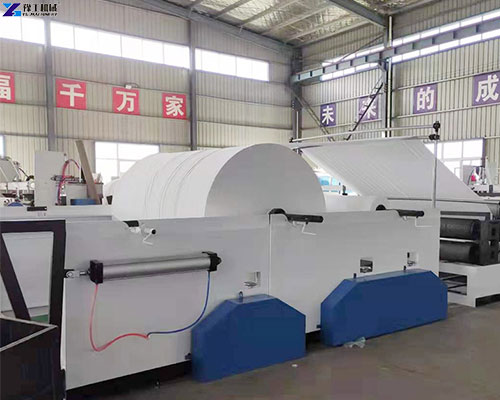

The small tissue paper making machine production line can produce raw materials to complete packages ready to sell toilet paper rolls. The production of toilet paper requires several machines to work together. We offer semi-automatic and fully automatic toilet paper making machines. The complete line includes a paper machine, a rewinder, a saw cutter, and a packaging machine. Tissue paper is an essential consumable in people’s daily lives and has a good market prospect. We can provide you with comprehensive services. If you need don’t hesitate to get in touch with us to get a detailed quotation!

Small Tissue Paper Making Machine Parameter

| Base paper width | ≤2100mm |

| Finished product diameter | Φ60~150mm(adjustable tightness) |

| Inner diameter of finished paper core | Φ 32~50mm |

| Base paper diameter | Φ1100mm |

| Inner diameter of base paper core | 3″ |

| Punching pitch (please specify) | 4 knives, mechanical adjustment 90 ~ 180mm |

| Rewinding speed | 0-200m/min |

| Punching method | Pneumatic separation |

| Return tray | 1-3layers |

| Overall dimension (L) × W × H) | 6500×3100×2600 (mm) |

| Machine weight | 3500kg |

| Total power | 4KW |

| Pneumatic system | 3 air compressors with a minimum pressure of 5kg / cm2 PA (provided by the customer) |

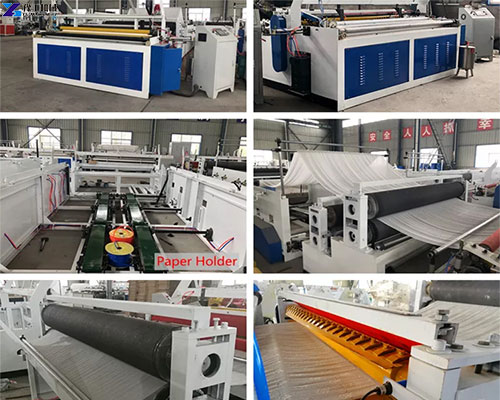

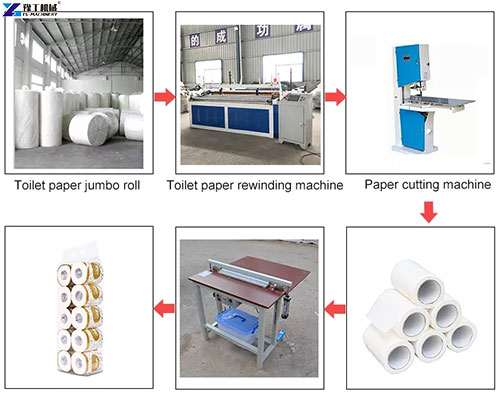

Tissue Paper Machine for Sale Production Process

Small tissue paper making machines and automatic toilet paper production processes are the same. They contain machines such as toilet paper rewinder (the machine can automatically load, emboss, punch, rewind, trim and spray glue, and seal the end), toilet paper saw cutter (to slice the long strips of paper made by the rewinder into small rolls), and toilet paper wrapping machine (manual water-cooled sealing machine/full-automatic round roll wrapping machine). The specific production process is shown below:

Finished Products Show

Features of Tissue Paper Production Machine

- The toilet paper rewinding machine adopts PLC computer programming, frequency conversion speed regulation, and pneumatic control. The machine integrates the functions of paper rolling, punching, automatic paper pushing, automatic lever pressing, pump shaft compressing, automatic trimming, and glue spraying. The whole process does not need manual operation!

- The automatic toilet roll-cutting machine will continue to cut long rolls of toilet paper into small sections of toilet paper rolls. The machine’s whole mechanism is sturdy, and the rolling paper cutting surface is flat. Cutting efficiency is high, stable at 50-70 cuts per minute.

- Full-automatic toilet paper packing machine, the machine can automatically bag and seal the cut toilet paper. The machine adopts a PLC controller and servo motor control and uses advanced components at home and abroad. The whole machine has stable performance and wide applicability.

Investment Suggestions for Toilet Paper Production Line

- In-depth understanding of market demand: Before investing in tissue paper making, it is recommended that you fully understand your local market demand. Then conduct market research and analysis to determine the target consumer groups and market demand characteristics. To be on the safe side, you can invest in a small tissue paper making machine first.

- Focus on product quality and performance: Investors need to combine their budgets to buy the highest-performance toilet paper production line or related equipment. This will improve the competitiveness of their toilet paper market.

- Expand sales channels: Investors can expand sales channels by establishing cooperative relationships with retailers and wholesalers. Also, use the Internet platform to expand sales markets and channels.

- Pay attention to environmental protection policy: Nowadays, the environmental protection policy of society is becoming more and more strict. We recommend that investors always pay attention to changes in environmental policies to ensure environmental compliance in the production process.

Tissue Paper Production Line Provided by YG

YG offers a wide range of equipment for the production of tissue paper. Examples include paper-making machines, paper rewinding machines, toilet paper cutting machines, and toilet roll packing machines that are needed after making paper. All of these machines can be used together to form fully automatic and semi-automatic small tissue paper making machine production lines. All of our machines are fully servo-automated tissue production lines. This helps you to ensure the pass rate of toilet paper rolls. Thus guaranteeing your market competitiveness. We also provide paper napkin making machines. Please click to get a free factory quotation!