The roll die cutting machine is an important post-press packaging processing and molding equipment. It can mainly carry out die cutting, creasing, hot stamping, laminating, and automatic waste discharge operations. The die-cutting machine can deal with non-metallic materials, self-adhesive, EVA, electronic components, etc. The die-cutting machine has the characteristics of high precision, high efficiency, and a high degree of automation. It can be used with paper cup machines and hamburger box machines. Click the button below to send a request, YG provides a free quote!

Roll Die Cutting Machine Parameters

| Model | YG850 | YG950 |

| Die-cutting area size | 850*280 mm | 950*550 mm |

| Die cutting rate | 100-180 times/min | 100-160 times/min |

| Accuracy error | ±0.15mm | ±0.15mm |

| Rated die-cutting pressure | 100T | 250T |

| Suitable for the base paperweight | 135-400gsm | 120-600gsm |

| Suitable for base paper width | 250-860mm | 250-960mm |

| Roll paper diameter | ≤1400mm | ≤1400mm |

| Roll paper reel specifications | 3“/6“/12“ | 3“/6“/12“ |

| Rated die-cutting air pressure | 0.5Mpa | 0.7Mpa, 1.5m³/min |

| Power supply | 5.5kw, 380v, 3 P, 50Hz | 11kw, 380v, 3 P, 50Hz |

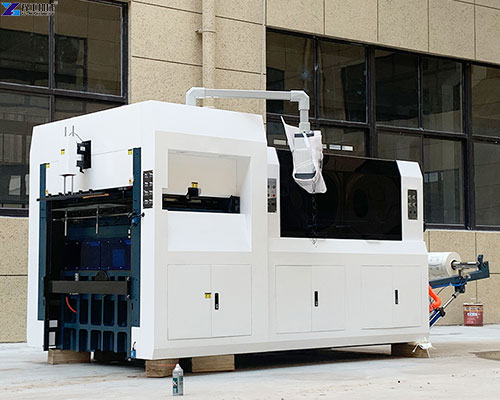

| Dimension | 2500*1700*1750mm | 4000*2100*1850mm |

| Machine weight | 3500kg | 7000kg |

| Noise | ≤100db | ≤120db |

Automatic Die Cutting And Creasing Machine Applications

The roll die cutting machine is widely used in the packaging and printing industry. In this field, die-cutting technology produces boxes, labels, cards, etc. in various shapes and sizes. It can specifically handle materials such as non-woven fabric, kraft paper, PE film, stickers, film, thermal paper, photos, greeting cards, paper plates, paper bags, X-ray film, hamburger paper, aluminum foil, cardboard, dinner plate paper, posters, and other products.

So it can also be used in electronic components, food packaging, gifts, clothing, dustproof materials, shockproof products, insulating materials, and other fields.

Paper Roll Punching Machine from YG

YG produces different kinds of roll die cutting machines, such as A-type slitting machines, C-type slitting machines, backrest slitting machines, gantry slitting machines, A4 paper slitting machines, single-roll direct-feeding transverse and vertical slitting machines, automatic collating and cross-cutting machine, etc. They have their specialties to deal with the products. They each have their types of products that they specialize in handling.

For example, printed paper, aluminum foil lunch boxes, dinner plate paper, photo paper, X-ray film, and very thin aluminum foil. We will recommend the right model of equipment based on the specific product you are handling. Click to tell us your needs!

6 Features of The Die Cutting Machine for Paper Cup

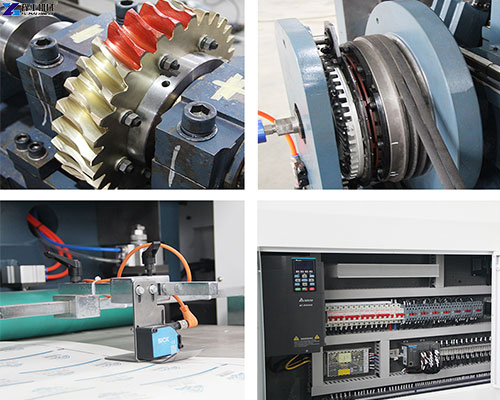

- The machine adopts three servo motor controls, automatic taper tension, and center winding methods.

- The main machine adopts frequency conversion speed regulation to keep the balanced operation in acceleration.

- The roll die cutting machine has automatic meter counting and alarm function. The rewinding adopts the structure of upper and lower A and B air-expanding shafts, chain

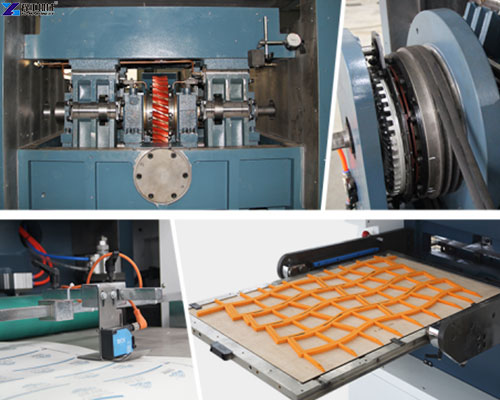

Automatic unloading, easy to operate. - The unwinding of the machine adopts an ultrasonic wave and CCD corrective correction system so that the irregular materials can be cut normally.

- It adopts round knife or flat knife longitudinal cutting slitting mode, high-pressure fan waste edge automatic exclusion device.

- The die-cutting machine for paper cups is also has a pneumatic expansion shaft automatic loading method or hydraulic shaftless automatic unwinding device.

Working Principle of Roll Die Cutting Machine

The working principle of the roll die cutting machine is mainly the use of die-cutting knives, steel knives, hardware molds, steel wire (or steel plate engraved into the template), through the embossing plate to apply a certain pressure, the print or cardboard rolled and cut into the required shape. Die-cutting technology includes die-cutting, creasing, hot stamping, laminating, and waste removal processes. It uses steel knives, hardware molds, etc. to apply pressure through the embossing plate to roll and cut the print or cardboard into a certain shape.

YG Paper Cup Fan Making Machine

We produce different types and models of roll die cutting machines. Each model has the type of product they specialize in handling. We will recommend the right model of die-cutting machine for your specific cutting material and size. Until now our die-cutting machines have been sold to Kazakhstan, Pakistan, UAE, Qatar, Saudi Arabia, Oman, Algeria, Egypt, Benin, and other countries. We also supply hamburger box machines, paper cup machines, napkin machines, toilet paper machines, paper bag machines, and other related equipment. Please contact us for more information about our equipment!