Rock crusher bucket for excavator, also known as excavator rock crusher bucket. It is a kind of accessory device installed on excavators and other construction machinery. It crushes and screens the materials by shearing, extruding, and impacting the materials. The crushing bucket is characterized by a compact structure, easy operation, and convenient maintenance. The crushing bucket is widely used in construction, road construction, and mining. Click the button below to get a detailed equipment quote!

Parameters of Excavator Rock Crusher Bucket

| SPECIFICATION | UNIT | YG-1 | YG-2 | YG-3 | YG-4 | YG-5 | YG-6 | YG-7 | YG-8 |

| Carrier Weight | Ton | 8-12 | 14-18 | 120-25 | 25-30 | 30-35 | 35-50 | 50-75 | ≥ 75 |

| Load Capacity | m³ | 0.15 | 0.55 | 0.66 | 0.70 | 0.90 | 1.30 | 1.60 | 2.30 |

| Opening Dimensions | mm | L540 H250 | L610 H510 | L740 H510 | L850 H510 | L910 H540 | L1205 H540 | L1300 H600 | L1450 H700 |

| Output Setting | mm | 15-60 | 15-60 | 15-130 | 15-135 | 15-140 | 15 – 145 | 40-150 | 100-200 |

| Length (A) | mm | 1240 | 1745 | 2000 | 2050 | 2185 | 2185 | 2930 | 3560 |

| Width (B) | mm | 1000 | 1000 | 1150 | 1300 | 1340 | 1620 | 1880 | 2090 |

| Height (C) | mm | 770 | 1100 | 1200 | 1400 | 1390 | 1390 | 170 | 2065 |

| Weight | Ton | 0.75 | 1.6 | 2.3 | 3 | 3.5a | 4.8 | 7.5 | 10.5 |

| Oil Flow | l/min | 90 | 98 | 140 | 160 | 180 | 210 | 320 | 380 |

| Pressure | bar | 200 | 220 | 220 | 220 | 220 | 220 | 250 | 230 |

| Counter | bar | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Max. Production | m³/h | 10 | 23 | 31 | 34 | 42 | 53 | 88 | 120 |

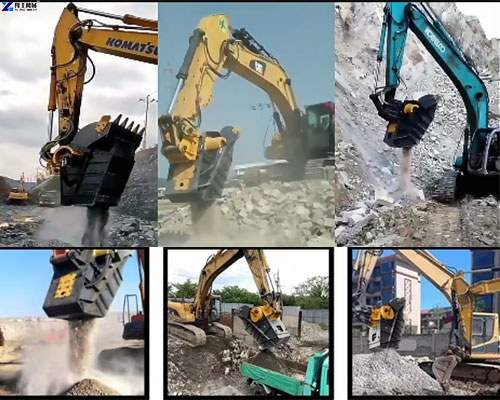

Application of Excavator Rock Crusher Bucket

- Demolition and cleaning: When demolishing old buildings, ruins, or obstacles, the crushing bucket can break the materials into small pieces for easy cleaning and transportation.

- Recycling and recovery: The crushing bucket can crush waste building materials such as concrete, bricks, and stones into reusable particles.

- Rock crushing: In the quarrying industry, the crushing hopper can break down large rocks into stones of the required size.

- Underground engineering: A crushing bucket can be used in underground excavation and digging tunnels to deal with rocks and hard soil.

- All kinds of stones: Concrete, bricks, cobbles, ores, asphalt, marble, gypsum, and so on.

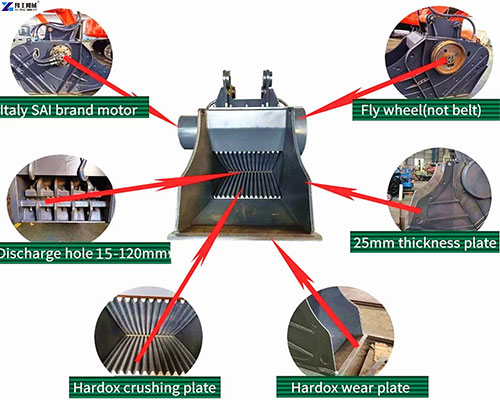

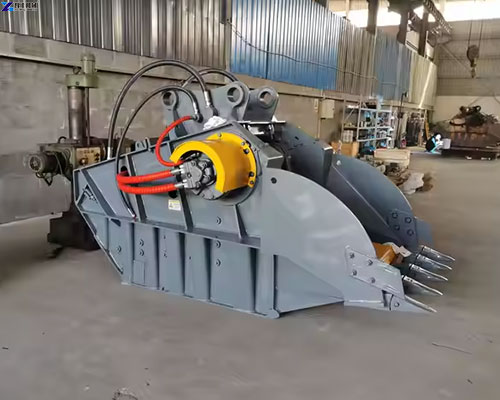

Crusher Bucket Attchement’s Main Parts

The main parts of a crushing bucket include the crushing head, driving system, adjusting mechanism, and so on.

- The crushing head is the core part of the crushing bucket, usually made of strong metal, which is used to apply huge impact and squeezing force to crush hard materials.

- The drive system is responsible for providing power to the crushing head to ensure its normal operation.

- The adjusting mechanism is used to adjust the crushing size of the crushing bucket to meet different project requirements.

Suggestions for Purchasing Excavator Rock Crusher Buckets

When purchasing a crushing bucket, the following factors should be considered comprehensively:

- Project requirements: Define the specific needs of the project, including the type of crushing material, hardness, particle size requirements, etc., to choose the most suitable type of crushing bucket.

- Performance parameters: Pay attention to the performance parameters of the crushing bucket, such as crushing force, crushing size, work efficiency, etc. These parameters will directly affect the crushing capacity and operational efficiency of the equipment.

- Brand and reputation: Choose a famous brand and a crushing bucket manufacturer with a good reputation to ensure the quality of the equipment and after-sales service.

Excavator Crusher Bucket Customer Applications

- Forest road maintenance in Serbia

Usage: The forest road has steep slopes and potholes caused by rainfall and vehicle traffic. To ensure the normal passage of the forest road, the Serbian forest management company introduced the crushing bucket. The customer uses the crusher to crush locally sourced material on-site, providing the stone needed for forest road maintenance. - Demolition of buildings in a European city

Application: The city was undergoing an urban renewal process that required the demolition of a large number of old buildings. The demolition process generates a large amount of construction waste, such as concrete blocks and bricks. To deal with these wastes and reduce the impact on the environment, the construction team introduced a crushing bucket to realize on-site recycling and reuse. - Mining in North America

Use: The rock extracted from this mine is so large that it is difficult to process and transport directly. To improve mining efficiency and reduce costs, the mine introduced the crushing bucket. People use the crushing bucket to initially process the mined rock. The large rocks are then crushed into smaller sizes for subsequent processing and transportation.

Customized Service for Excavator Crusher Bucket from YG

The excavator crushing bucket can be customized to match the excavator model above 15 tons. Due to the different specifications of different excavator models, each piece of equipment is matched according to the customer’s excavator. The hourly output of the crusher bucket with 15-ton excavator can be determined according to the size of the crushed particles; the hourly output of 60mm or so is about 30 tons. The hourly output of the excavator with more than 200 excavators can be up to 40 tons per hour. We provide customized services for most of our equipment. YG also provides water well drilling rigs, hydraulic core drilling rigs, down-the-hole drilling rigs, crawler water well drilling rigs, rotary drilling rigs, solar pile drivers, horizontal directional drilling, and other drilling rigs. Tell us your needs and get customized services!