The rebar straightening and cutting machine is one of the processing machines used to straighten and cut off steel bars with a diameter below 14mm. Its function is mainly to straighten and cut off at fixed size, which is suitable for dealing with cold rolled grade Ⅲ rebar for construction and can also straighten hot rolled disk round steel. YG-produced straightener and cutter has high automation, and fast hauling speed for a continuous working system. And is equipped with an automatic counting and stopping device, which is of good safety performance. The surface of the wire treated by this machine is scratch-free, and the straightness is good. At the same time, the equipment also has easy operation, is easy to adjust, drops simply, high production efficiency. Welcome to consult us, we will provide you with a competitive price and detailed information!

Straightening And Cutting Machine Parameter

| Model | YGT 4-14 | YGT 5-16 |

| Diameter adjustment range | 4-14mm ( Ⅲ grade steel) | 5-16mm ( Ⅲ grade steel) |

| Wire pulling speed | 50m/min | 50m/min |

| Traction motor power | 2.2kw-6 | 2.2kw-6 |

| Modulation motor power | 7.5kw-4 | 15kw-4 |

| Cut off motor power | 5.5kw | 5.5kw-4 |

| Cutting error | ±0.5-1cm | ±0.5-1cm |

| Wire length | 800-9000mm (can be lengthened) | 800-9000mm (can be lengthened) |

| straightening degree | ±2 mm/m | ±2 mm/m |

| Weight | 1500kg | 1500kg |

| Size | 2800*650*1200mm | 3300*650*1300mm |

Rebar Steel Wire Straightener Type and Function

There are many types of wire straighteners and cutters produced by YG, which can deal with different diameters and quantities of steel bars, the following are the 3 main categories of the machine:

- Ordinary models 5.5kw-7kw as long as a motor, the internal structure is similar, the configuration is different, according to the rebar composition containing impurities, a set of wear parts straighten about 300-500 tons of steel.

- Thousand tons models. According to the rebar composition containing impurities, a set of perishable parts straighten 800-1000 tons of rebar.

- Frequency conversion model. A set of wearing parts straighten 800-1000 tons of steel. The speed of this type of steel wire straightener is adjustable, and the length is adjustable. Discharge on the ground is suitable for short material; with a traction bar can be all out.

The Use of A Steel Wire Straightener

Widely used in construction projects, highways, bridge projects concrete components, prefabricated panels factory straightening discs, coil rebar, etc. It is the ideal straightening machine for large and medium-sized processing users. Besides, it can straighten and cut off stainless steel wire, aluminum wire, cold-drawn wire, and steel wire with plastic skin. The processed products cut flush, with small errors, and good performance. The cutting length of the machine can also be customized according to customer requirements.YG’s steel wire straightener and cutter have excellent performance and reasonable price.

Structure of Wire Straightening Machine for Sale

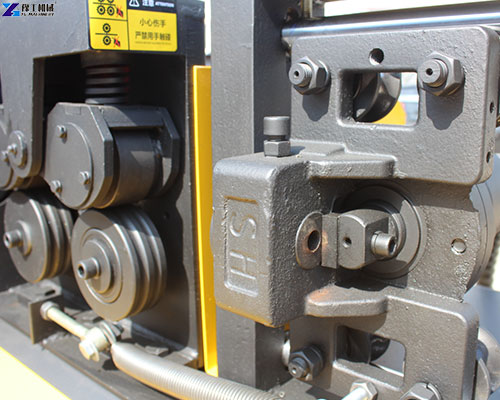

Steel bar straightening and cutting machines mainly consist of straightening cylinders, drafting mechanisms, cutting mechanisms, steel bar fixing frames, frames, and driving devices.

Steel Wire Straightener Wearing Parts

The wearing parts of the steel bar straightener and cutter mainly include the meter counter, solenoid valve, straightening wheel, meter wheel, multi-slot wheel, feed roller, feed wheel, and triangle belt. YG provides steel bar straightening and cutting machines with good quality and long service life, if the wearing parts need to be replaced after a long time of use and wear and tear, you can contact us to get it!

6 Strengths of Straightening & Cutting Machine

- Automatic control. Adopt microcomputer control, automatic length, automatic root number, and automatic cutting.

- Arbitrary switching. Travel switch baffle type and encoder signal are two ways to switch arbitrarily.

- Convenient. Multiple batches of simultaneous input length and quantity, computerized storage memory, convenient.

- Simple operation. Simple operation, smooth running, low failure rate, and easy maintenance.

- Simple machine structure, mature industrial design, and technology to ensure stable and reliable product quality.

- Full-automatic CNC hydraulic straightening machine, straightening and cutting off assembly line operation, greatly improving work efficiency.

Working principle of wire straightening machine for sale

Firstly, the electric motor increases the speed through belt transmission, so that the straightening cylinder rotates at high speed, the steel bar through the straightening cylinder is straightened, and the rust skin on the surface of the steel bar is removed by the straightening mold. When the steel bar is adjusted to a predetermined length, the hammer head strikes the upper cutter frame to cut the steel bar, and when the cut steel bar falls into the feed frame, the cutter table returns to the original position due to the action of the spring, completing a cycle.

Wire Straightening Machine for Sale Exported to Vietnam

Last month we exported a rebar straightening machine to Vietnam, the customer is an employee of a construction company. They need a new steel bar straightener and cutter to deal with rebar for construction. Through searching the customer learned that we are a professional manufacturer of rebar machinery and communicated with us further. Our sales manager recommended a GTQ4-12 kiloton steel bar straightening and cutting machine to understand the customer’s needs. We provided a detailed quotation to the customer, and the customer decided to buy it from us. Now our Wire Straightener and Cutter have been exported to many countries, such as Thailand, Myanmar, Nepal, Indonesia, Malaysia, Brunei, Philippines, Russia, Kenya, Nigeria, Mexico, and so on. We also keep long-term cooperation with many of these customers.

YG Recommends The Right Steel Wire Straightener for You

We generally recommend the right type of machine to our customers according to the specific rebar they are dealing with. Before recommending the machine, we generally confirm the following questions to the customer:

- What is the type of rebar to be processed?

- What is the diameter of the rebar?

- What is the shortest cutting length?

Understanding the customer’s needs is the only way to better recommend the right machine, we are a professional steel bar straightening and cutting machine manufacturer. We also produce other rebar machinery such as thread rolling machines and upsetting machines. We will provide you with high-quality equipment at and competitive price!

Maintenance of steel bar straightening and cutting machine

1. Use paint or lubricant to prevent rust.

The automatic steel bar straightener and cutter should always be kept clean. A newly purchased rebar straightening and cutting machine has been painted. When the machine is not in use, please try to paint or apply lubricant to prevent the machine from rusting, especially the blade parts. Lubrication reduces wear and tear on the contact surfaces in relative motion and serves to cool, dissipate heat, prevent rust, and clean up wear debris.

2. Check whether the attachment is firm.

The steel bar straightening and cutting machine often checks whether the bolts and other attachments of each part are firm. If the attachments are not firm, it will cause noise pollution, which will affect the workers and the machine itself. Machine operation is usually a long time, high-intensity environment.