The rebar forging machine is a device that uses the principle of hydraulic cold heading to increase the diameter of the rebar end. Generally, the treated rebar end will increase by 4~6mm. After enlargement, the thread is processed. The actual cross-sectional area of the treated rebar becomes larger, which greatly improves the tensile strength of the joint. In general, the end of the rebar after roughing needs further processing by the rebar thread rolling machine. The treated rebars can be better connected. These rebars are suitable for projects with high requirements for construction, roads and bridges, high-speed railways, and power stations. The high performance, high precision, low flow rate, and low energy consumption of the hydraulic roughing machine have won the love and support of many construction site customers. YG provides various rebar machinery and equipment, such as rebar straightening and cutting machines, thread rolling machines, steel sleeves, rebar press machines, etc. They are of high quality, wear-resistant, simple and convenient to operate, save labor, and can be processed and produced continuously.

Parameter of Rebar Cold Forging Machine

| Model | HDCJ-32 | HDCJ-40 | GDCJ-40 |

| Processing Reinforcement Range | 12~32mm | 12~40mm | 12~40mm |

| Motor Power | 4Kw | 7.5Kw | 4Kw |

| Max.Flow | 5.42L/min | 4.0L/min | 6.4L/min |

| Pressure | 2036KN | 3000KN | 2036KN |

| Max Working Pressure | 80MPa | 31.5MPa | 80MPa |

| Dimension | 1020*500*965mm | 1300*830*1350mm | 1300*650*965mm |

| Weight | 560Kg | 900Kg | 600Kg |

Application of Rebar Forging Machine

Rebar roughing machine has a wide range of applications in the field of construction engineering. We usually use the rebar roughing machine in projects with high requirements for the connection of rebars, such as construction engineering, road and bridge engineering, high-speed railway engineering, power station engineering, etc. YG produces a single-cylinder rebar forging machine and a double-bar roughing machine. They are easy to operate, fast in processing, and can significantly improve work efficiency. You are welcome to come and consult!

Finished Product of Rebar Upsetting Machine

The figure below shows the upsetting products and the rolled steel bars. Generally, people use the upsetting machine and the rolling machine together. Then, the steel bars are connected according to their needs.

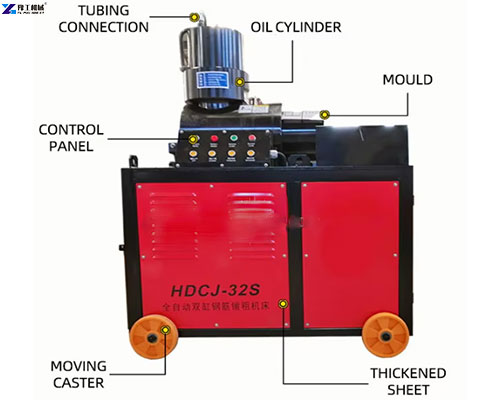

The Structure of The Rebar End Upsetting Machine

The steel bar upsetting machine consists of a body, a downward pressure cylinder, a forward cylinder, a theme, a mold, an upsetting head, an electrical control system, a hydraulic system, and other parts. The specific rebar forging machine structure is as follows:

6 Major Advantages of Rebar Upsetting Machine

- High strength: The net cross-sectional area of the upsetting section steel bar after cutting the thread is still larger than the original cross-sectional area of the steel bar, that is, the thread does not weaken the cross-section, so as to ensure that the joint strength is greater than the strength of the steel bar parent material.

- Stable performance: The tightening torque will not affect the strength of the joint. The loose thread or less screwing in 2 to 3 threads will not significantly affect the strength of the joint, eliminating the influence of artificial factors and force measuring tools on the performance of the joint.

- Fast connection speed: Use the connecting sleeve to connect the steel bar and tighten it. Due to the large thread pitch and the small number of threads, there is no need to use a torque wrench, which speeds up the connection speed.

- High production efficiency: On-site upsetting and cutting of a thread head only take 30 to 50 seconds, and each set of rebar forging machines can process 400 to 600 thread heads per shift.

- Simple operation, users don’t need a professional technician to operate the machine with the hydraulic and electrical control. We can start and operate it in ten minutes.

- The equipment has a low failure rate, no vulnerable parts, and low construction cost.

Safe Operation of Rebar Upset Cold Forging Machine

- The staff must undergo technical training and pass the skill assessment before they can start working.

- Before formal processing, we should debug and run empty for 2-3 minutes. And then we can operate after it is normal.

- The cutting edge of the steel bar is straight and there should be no bending.

- Before processing the steel bar, the rebar forging machine should return to the initial position before processing to ensure consistent processing work.

- There should be no transverse cracks in the processed steel bar. We should eliminate the equipment failures in time.

- Refueling should be clean 46 hydraulic oil.

- The staff should comply with the safety protection regulations for engineering personnel.

Precautions for The Use of Rebar Roughing Machine

- The cooling liquid must use water-soluble emulsified coolant. Do not use oily coolants, much less ordinary lubricants.

- Do not roll threads without coolant.

- The end of the steel bar should be flat and we should cut it with a toothless saw. It should be round and straight within the length of 500mm at the end. Don’t allow bending, and directly process the end of the gas cutting or cutting machine.

- The feed should be uniform during the initial cutting and do not rush to prevent the blade from cracking.

- We should clean and oil the slideway and slider of the rebar forging machine regularly.

- Users should clean iron filings in time.

- Cleaning the cooling liquid tank once every half a month.

- Refuel the reducer regularly to maintain the specified oil level.

- Maintain the rolling machine regularly.

- We need to ground the machine enclosure reliably before use.

Rebar Cold Forging Machine from YG Equipment

YG provides single-cylinder upsetting and double-cylinder upsetting machines. This equipment is the key equipment to achieve steel bar connection. The rebar upsetting machine provided by YG is simple to operate, fast, and has high processing quality. It is conducive to ensuring the structural quality of construction projects. So far, our rebar upsetting machine has been sold to Malaysia, Mexico, the United States, Singapore, Kuwait, Turkey, and other countries. We manufacture high-quality rebar hoop bending machines, rebar thread rolling machines, rebar cutting machines, CNC rebar bending machines, rebar rust removal machines, chain link fence machines, etc. Contact us to get the latest equipment quotation!