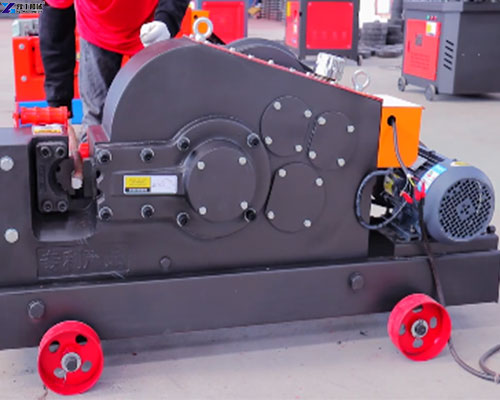

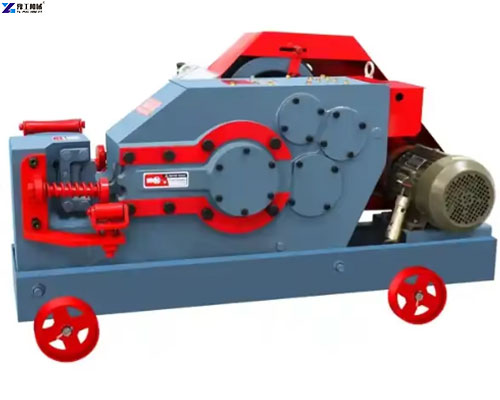

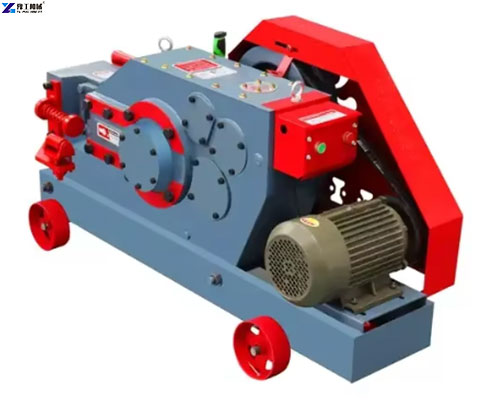

A rebar cutting machine is a professional fixed-length cutting equipment for rebar. It is a machine that will be used in many fields, such as concrete construction, bridges, tunnels, roads, etc. The rebar cutting machine produced by YG has two types: fully automatic rebar cutting machine and semi-automatic rebar cutting machine. It can handle various types of rebars, such as ordinary carbon steel such as Q235-A, hot-rolled round steel, threaded steel, flat steel, square steel, and other steel materials. The rebar cutting machine produced by YG has the characteristics of lightweight, low energy consumption, stable operation, and high efficiency.

Parameters of Rebar Cutting Machine

| Model | Technical Parameter | |

| YG-40/YG-40S | Motor Power(kW) | 2.2 |

| Rebar Diameter(mm) | 6-25 | |

| Round Bar Diameter(mm) | 6-26 | |

| Cutting Number(times/min) | 32 | |

| Weight(kg) | 300 | |

| Dimension(mm) | 1200*310*630 | |

| YG-40A | Motor Power(kW) | 3 |

| Rebar Diameter(mm) | 6-28 | |

| Round Bar Diameter(mm) | 6-35 | |

| Cutting Number(times/min) | 32 | |

| Weight(kg) | 330 | |

| Dimension(mm) | 1310*460*760 | |

| YG-40B | Motor Power(kW) | 3 |

| Rebar Diameter(mm) | 6-32 | |

| Round Bar Diameter(mm) | 6-35 | |

| Cutting Number(times/min) | 32 | |

| Weight(kg) | 350 | |

| Dimension(mm) | 1310*460*760 | |

| YG-42 | Motor Power(kW) | 3 |

| Rebar Diameter(mm) | 6-32 | |

| Round Bar Diameter(mm) | 6-40 | |

| Cutting Number(times/min) | 32 | |

| Weight(kg) | 380 | |

| Dimension(mm) | 1330*460*790 | |

| YG-45 | Motor Power(kW) | 4 |

| Rebar Diameter(mm) | 6-32 | |

| Round Bar Diameter(mm) | 6-40 | |

| Cutting Number(times/min) | 32 | |

| Weight(kg) | 400 | |

| Dimension(mm) | 1330*460*790 | |

| YG-50 | Motor Power(kW) | 4 |

| Rebar Diameter(mm) | 6-40 | |

| Round Bar Diameter(mm) | 6-45 | |

| Cutting Number(times/min) | 28 | |

| Weight(kg) | 480 | |

| Dimension(mm) | 1410*460*810 | |

| YG-40 Straight Thread Rebar | Motor Power(kW) | 3 |

| Rebar Diameter(mm) | 6-28 | |

| Round Bar Diameter(mm) | 6-35 | |

| Cutting Number(times/min) | 32 | |

| Weight(kg) | 370 | |

| Dimension(mm) | 1330*460*790 | |

| YG-45 Straight Thread Rebar | Motor Power(kW) | 4 |

| Rebar Diameter(mm) | 6-32 | |

| Round Bar Diameter(mm) | 6-40 | |

| Cutting Number(times/min) | 32 | |

| Weight(kg) | 410 | |

| Dimension(mm) | 1330*460*790 | |

| YG-50 Straight Thread Rebar | Motor Power(kW) | 4 |

| Rebar Diameter(mm) | 6-40 | |

| Round Bar Diameter(mm) | 6-50 | |

| Cutting Number(times/min) | 28 | |

| Weight(kg) | 510 | |

| Dimension(mm) | 1410*460*810 | |

| YG-50 Angled Steel Bar | Motor Power(kW) | 4 |

| Angled Bar Diameter(mm) | ≤100*100*10 | |

| Cutting Number(times/min) | 28 | |

| Weight(kg) | 580 | |

| Dimension(mm) | 1440*460*810 | |

| YG-50 Flat Steel Bar | Motor Power(kW) | 4 |

| Flat Bar Diameter(mm) | 150*10 | |

| Cutting Number(times/min) | 28 | |

| Weight(kg) | 580 | |

| Dimension(mm) | 1440*460*810 | |

Types of Rebar Cutting Machine

There are two types: fully automatic rebar cutting machines and semi-automatic rebar cutting machines. The power of the fully automatic rebar cutting machine is the motor. The motor converts the electric energy into kinetic energy to control the cutting knife to cut the rebar. The semi-automatic one is manually controlled to cut the rebar.

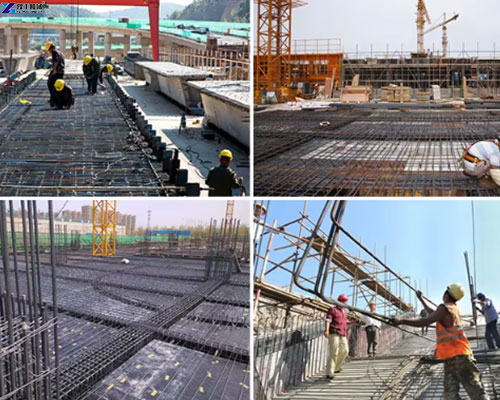

Application Occasions of Rebar Cutting Machine

Rebar cutting machine plays an important role in construction sites, bridge construction, tunnel construction, and other places. It is an indispensable piece of equipment in the rebar processing link. It can handle various types of steel bars, which are used in most engineering buildings. Through precise cutting operations, steel bars that meet the length requirements can be made. This provides strong support for subsequent steel bar processing and installation.

Working Principle of Steel Bar Cutting Machine

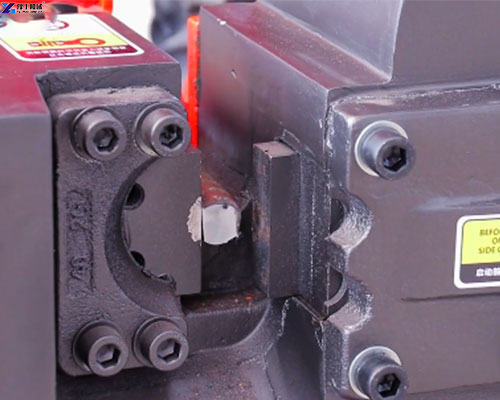

The working principle of the steel bar-cutting machine is mainly driven by an electric motor. The rotation of the motor drives the large pulley to rotate and then drives the coupling gear, large gear, crankshaft, and other components to operate. These rotations will eventually transmit the torsional force to the shear connecting rod, pushing the scissors knife seat to achieve the purpose of shearing the steel bar.

Features of Steel Bar Cutting Machine

- Compact structure: The steel bar cutting machine is small in size and light in weight. The structure of the whole machine is compact, the equipment is solid and durable, and it is suitable for use in various working environments.

- High efficiency and energy saving: Compared with other cutting equipment, the steel bar cutting machine consumes less energy and has high working efficiency. These characteristics can significantly improve the efficiency and quality of steel bar processing.

- Wide range of applications: It is suitable for cutting various ordinary carbon steels, hot-rolled round steels, threaded steels, flat steels, and square steels to meet the needs of different projects.

Maintenance of Steel Bar Cutting Machine

Regularly check and maintain the machine. To ensure normal operation and extend the service life of the rebar cutting machine, we need to check and maintain the rebar cutting machine regularly. The inspection content mainly includes checking whether the cutter has cracks, tightening bolts, adjusting the cutter gap, etc. At the same time, it is necessary to promptly remove the broken heads and debris near the cutter, clean and lubricate the whole machine, etc. Timely and regular inspection and maintenance can help the rebar-cutting machine work better and extend its service life.

Rebar Processing Equipment Produced by YG

YG manufactures various equipment related to rebars, such as rebar straightening and cutting machines, rebar thickening machines, rebar thread rolling machines, rebar bending machines, etc. We have advanced manufacturing equipment and strong production capacity. We have strong production capacity and abundant inventory and can deliver goods to you quickly. Therefore, our rebar cutting machine is of high quality and low price. If you need this machine, please contact us for machine quotes and detailed information!