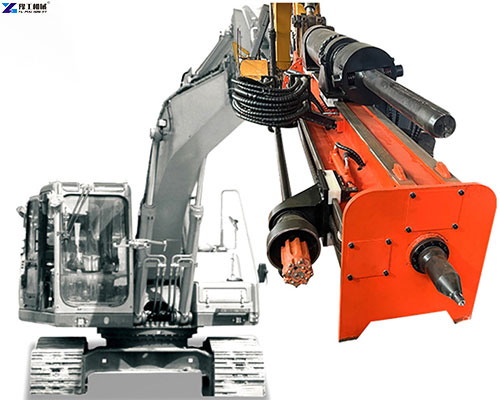

The integrated rock dill and splitter have both drilling and splitting functions. It is driven by the power system of the excavator to crush and decompose the rock. Because it is installed on the excavator’s arm, it is easy to operate and move, and its working efficiency is about 20 times higher than that of traditional blasting. At the same time, it can generate 6,000 tons of thrust, which can easily crack thousands of cubic meters of hard rock. Therefore, the drilling and splitting machine greatly improves the efficiency of rock cracking, has concentrated functions, and is more intelligent. YG also produces small splitters, which are suitable for use in small sites or underground occasions. YG welcomes you to consult!

Integrated Rock Drill and Splitter Technical Information

| Rock Drilling Machine | |||

| Power | Drilling hole diameter | Drilling depth | Drilling speed |

| 24kw | Middle 120mm | 1600mm | 1m/min |

| Splitting Machine | |||

| Splitting depth | Splitting force | Rotation angle | – |

| 1000MM | 8000T | 120° | – |

| Push Beam | |||

| Rock drilling maximum propulsion | Splitting maximum pullout force | ||

| 25KN | 70KN | ||

| Excavator requirements:>25T | |||

Application Occasions of Integrated Rock Drill and Splitter

- Stone mining operations: Rock drilling and splitting machines have been widely used in mining rough materials in precious quarries such as marble, granite, and sandstone. Compared with blasting or other manual methods, integrated rock drill and splitter have the advantages of safety, environmental protection, high yield rate, and low mining cost.

- Demolition of concrete components: Mainly refers to partial and complete demolition of cement pavement, reinforced concrete pile heads, bridge and house components, dams, hydropower station hydraulic structures, bridge piers, airport runways, high-grade highways, bridge decks, etc.

- Treatment of gravel on dangerous rock slopes of water conservancy and hydropower.

- It can also be used for the construction of non-excavation pipelines and the removal of road-blocking boulders;

- It can also break rocks in real estate foundation pits.

Workflow of Integrated Rock Drill and Splitter

The workflow of the integrated rock drill and splitter is roughly as follows:

- Find the positioning point.

- Position the positioning axis of the drilling and splitting machine.

- The rock drill starts drilling.

- The low-pressure impact is turned on.

- Turn on the dust removal device.

- The dust cover is lowered.

- High-pressure impact is turned on.

- The dust cover returns to its position.

- Lift the rock drill back to its position.

- Turn off the dust removal device.

- The main frame rotates. Align the splitting head with the drilling position.

- The splitter rotates to determine the splitting direction.

- The splitting head is inserted into the drill hole.

- Split the hard rock.

- The splitting head returns to its original position.

Working Principle of Excavator Mounted Hydraulic Rock Splitter

The drilling and splitting machine uses ultra-high-pressure oil as its energy source. The hydraulic power station’s output of ultra-high-pressure oil is mechanically amplified by the supercharger. Then, the supercharger drives the oil cylinder in the hydraulic rod to generate a huge driving force, so that the splitter pushes the hydraulic top in the splitting rod to extend outward to crack the rock. The hydraulic pressure is instantly ultra-high.

6 Advantages of the Drilling and Splitting Machine

- Diverse functions: The integrated rock drill and splitter can achieve multiple uses. It can be used to drill holes with a rock drill and split rocks with a splitter. After the drilling and splitting machine head is disassembled, it can also be restored to an excavator for excavation operations.

- High safety: During the use of the drilling and splitting machine, the machine automatically completes most of the work, and the workers operate in the cab, reducing the safety risks that may be caused by work fatigue and direct operation.

- Good operability: The excavator’s built-in walking structure can cope with all kinds of muddy and uneven roads. At the same time, people can operate it in a cab or remotely by remote control.

- The rock drilling speed is fast, and the speed can reach one meter per minute on rocks with a hardness of 7.6 degrees.

- The drilling cost is low and the efficiency is higher than that of pneumatic rock drilling vehicles.

- Environmental protection: The Hydraulic Rock Drill and Splitter has the characteristics of low vibration, low noise, and low dust when performing building demolition and rock splitting operations.

How to Install the Hydraulic Rock Drill and Splitter?

- Before installing the integrated rock drill and splitter, remove the bucket or any other auxiliary tools on the excavator’s forearm, and then use the bucket shaft to firmly install the drilling and cracking machine on the forearm.

- The excavator needs to be modified as necessary, that is, the pipeline of the breaker is adjusted to connect with the oil inlet and outlet of the drilling and cracking machine. At the same time, the air compressor equipped with this machine needs to be fixed on the excavator, and its oil port needs to be connected to the breaker pipeline system through the priority valve. Next, connect the air pipe of the air compressor to the air pipe joint of the drilling and splitting machine, and ensure that the line interface of the wireless remote control receiver is also correctly connected.

- There is a special oil return pipeline in the hydraulic system of the drilling and splitting machine. This pipeline must remain independent and must not be mixed with other oil return pipelines. Instead, it is directly connected to the oil tank of the excavator (the connection with the oil return pipe can be achieved by welding an adapter on the oil tank cap). After completing the above steps, the installation of the drilling and splitting machine is completed.

Maintenance of the Hydraulic Rock Drill & Splitter

- Indicate that the grease nozzle needs to be regularly filled with lubricating grease every shift, and lubricating oil is regularly applied to the slideway of the integrated rock drill and splitter. After each shift, check whether the oil pipe is leaking, whether the bolts are loose, etc.

- The wearing parts of the Hydraulic Rock Drill & Splitter (such as drill bit, drill rod, drill rod sleeve, and splitting head) should be checked at any time. If damaged, the accessories should be replaced in time to avoid damage to other parts of the machine body other than the accessories.

Precautions for Use of Excavator Mounted Rock Splitter

- After drilling and after the cracking tool is put into the hole, it is strictly forbidden to move the excavator, and it is strictly forbidden to (turn the frame left or right).

- When drilling, make sure that the air compressor is operating normally and the air pressure is normal. It is strictly forbidden to drill without air.

- After drilling in place, lift the dust cover first and then lift the drilling rig.

- Forward rotation is used to disassemble the drill bit and drill rod, and it is useless at other times.

- Fill the oil tank above the drilling rig with lubricating oil. Fill it every four hours to ensure that the rock drill is fully lubricated. If there is no mist spraying out of the exhaust hole, stop the machine and add lubricating oil.

- It is strictly forbidden to vibrate the integrated rock drill and splitter in the air.

- Clean the built-in filter of the vacuum cleaner regularly.

YG Related Product Recommendations

In addition to the drilling and cracking machine, we also produce related cutting and demolition equipment and drilling equipment. For example, hydraulic wire saws, hydraulic wall saws, water well drilling rigs, hydraulic shears, hydraulic hammers for excavator attachments, rotary drilling rigs, photovoltaic pile drivers, steel bar thread rolling machines, steel bar straightening and cutting machines, and other equipment. Our equipment is of high quality and low price and is popular in domestic and foreign markets. We also have long-term foreign customers. YG has a strong production capacity and can quickly provide you with the equipment you need. If you have any needs, please contact us to get a free quote for the equipment!