The hydraulic wall saw is mainly used for cutting reinforced concrete walls, brick walls, bridges, stones, etc. The equipment power is hydraulics, it has a powerful cutting effect and has a wider range of applications. It is a powerful assistant for construction projects and stone mining. In addition, the saw has the characteristics of no dust, high efficiency, smooth cutting, and accurate size. The hydraulic wall saws produced by YG have the advantages of strong power, customizability, simple and safe operation, and economical and affordable. Please get in touch with us for more details!

Hydraulic wall saw parameters

| Hydraulic Oil Pump | Model | YG 600 | YG 700 |

| Max. power | 25KW | 30KW | |

| Motor cooling method | Air cooling | water cooling | |

| Rated voltage | 380V 50HZ | 380V-420V 50HZ-60HZ | |

| Pressure stages | 3 | 3 | |

| Max. operating pressure | 200bar/20Mpa | 210bar/21Mpa | |

| Oil flow rate | 30-80L/min | 40-100L/min | |

| Dimensions | 600mm*650mm*1050mm | 500mm*520mm*1100mm | |

| Weight | 220kg | 140kg | |

| WallSaw | Saw blade diameter range | 800-1400mm | 800-1600mm |

| Cutting depth | 620mm | 730mm | |

| Max. working pressure | 180bar/18Mpa | 200bar/20Mpa | |

| Max. oil flow rate | 100l/min | 100l/min | |

| Gearing | Gear | Gear | |

| Rotation speed | 450/950/1300Rpm | 450/850/1200Rpm | |

| Dimension | 400mm*420mm*400mm | 400mm*420mm*400mm | |

| Weight | 38kg | 39kg |

Concrete wall saw for sale application

- Application industries of concrete wall saw: construction projects, stone cutting and mining, and reinforcement construction fields.

- Specific applications: include opening doors, windows, and vents on walls, ceilings, and floors, elevator shaft HVAC systems, cutting reinforced concrete beams and columns, cutting floor slabs and bridges, and stone-cutting processing.

- The most widely used industries: now hydraulic wall saws have become the leading cutting construction equipment in the demolition and demolition construction of demolition companies and demolition companies. It replaces the traditional construction methods of strong chiseling or drilling holes.

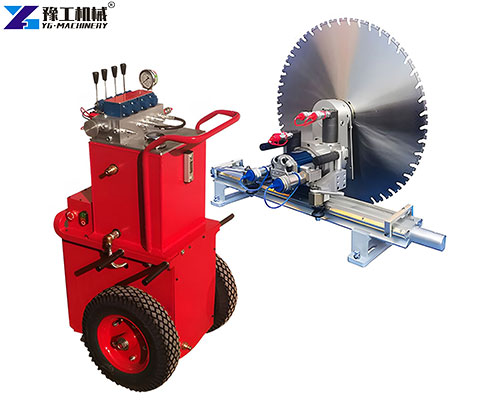

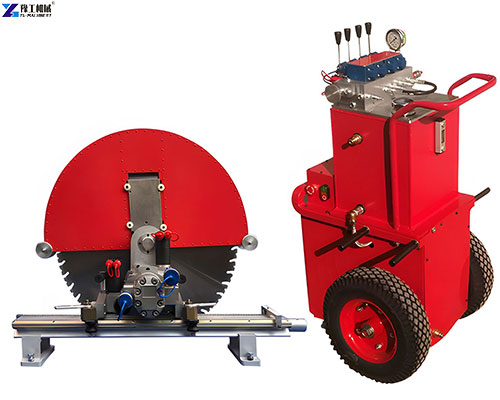

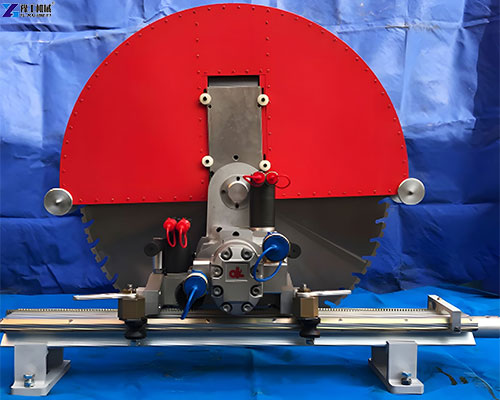

Wall mounted concrete saw components

Wall mounted concrete saw mainly includes hydraulic power station and hydraulic saw heads. The user places the hydraulic power station on the ground. Then the saw head runs on the wall; it provides power to the saw head, and hydraulic oil pipes connect them. The following is the detailed information on wall-mounted concrete saw components :

- Hydraulic pump station

- Wall saw head

- 1 meter * 1 guide rail

- 2 meters * 1 guide rail

- 10 meters * 6 oil pipes

- Saw cover 850mm (depending on the size of the saw blade)

- Saw blade 800mm (different saw blade sizes for different needs)

- 4 guide rail mounting brackets

- 4 track stops

- 1 toolbox

Concrete wall cutting saw workflow

The construction process of a hydraulic wall saw usually includes the following steps:

- Fixing of circular saw: Fix the circular saw in the predetermined position to ensure cutting accuracy and stability.

- Guide rail installation: Install matching guide rails and fix them with high-strength anchor bolts. During the installation process, a laser locator will help determine the track connection.

- Cutting parameter selection: According to the material, select appropriate cutting parameters, such as the circumferential speed of the diamond saw blade and cutting depth.

- Cutting operation: Start the hydraulic concrete wall saw for the cutting operation. During the cutting process, pay attention to maintaining the stable operation of the saw blade and a sufficient supply of cooling water.

- Post-cutting treatment: After the cutting is completed, the cutting surface is cleaned and processed to ensure the construction quality and aesthetics.

Working principle of hydraulic wall saw

The working principle of a concrete wall cutting saw is that the diamond saw blade moves along the track direction. And rotates at high speed under the drive of a hydraulic or electric motor. Then cuts hard materials such as reinforced concrete by grinding and cutting. During the cutting process, the water will cool and flush away the dust and generated powder to ensure smooth cutting. Finally, the incision processed by the hydraulic concrete wall saw is smooth and beautiful.

What are the benefits of using concrete wall saws?

- Fast cutting speed: The concrete wall saw uses a diamond saw blade, which can rotate at high speed and move along the track direction under the drive of a hydraulic or electric motor. This cutting method is faster than traditional methods.

- Smooth cutting: The linear cutting method of the concrete wall cutting saw makes the construction section more neat, the cutting accuracy is higher, and the cutting surface is smooth and beautiful.

- Environmental protection and safety: The noise generated during the cutting process of the concrete wall cutting saw is low and the dust is very little. Water cooling and flushing will remove the dust during work, thereby reducing the harm to the health of construction workers and the pollution to the environment.

- Easy to operate: The structural design and control system of the hydraulic wall saw are simple and clear, allowing operators to easily master and operate proficiently.

- Safe and reliable: The concrete wall saw for sale has an overload protection function and can automatically shut down when overloaded to protect the safety of equipment and personnel. In addition, its hydraulic system itself is very safe.

Trusted concrete wall saw for sale from YG

YG produces various construction machinery, in addition to hydraulic wall saws, there are high-frequency wall saws, electric wall saws, hydraulic wire saws, high-frequency wire saws, electric wire saws, rock splitters, various drilling rigs, concrete pumps, and other related machinery. So far, our production equipment has been quite advanced and mature. And our R&D and production teams are committed to producing high-quality products for customers. We have delivered the wall saw equipment to many countries including Singapore, Australia, Brunei, Saudi Arabia, Israel, Brazil, Madagascar, Philippines, etc. They are satisfied with our products and services, and we have maintained a long-term cooperative relationship. You are welcome to consult our equipment at any time!