The hydraulic thread rolling machine is mainly used to deal with ribbed steel bars in construction projects. This equipment can process the end of the rebar into standard threads to facilitate the connection and fixing of the rebar. Through the treatment and cold hardening effect of the steel bar by the wire rolling wheel, the strength of the head of the steel bar is significantly improved to reach the same level of strength as that of the parent material. This kind of equipment is widely used in construction, bridges, tunnels, and other engineering fields, and is one of the indispensable and important equipment for rebar processing. Generally, the wire rolling machine will be used in conjunction with the dunnage machine, the order of use is first through the rebar forging machine for steel bar dunnage and then rolled wire processing. YG provides a variety of various construction machinery, you are welcome to come to the consultation, and we will provide you with a competitive price!

Parameters of coupler threading machine

| Model | YG28-40 | YG28-80 | YG28-150 | YG28-185 | YG28-200 |

| Max rolling pressure | 120KN | 150kn | 150kn | 180kn | 200kn |

| Hydraulic diameter | 5-36MM | 6-42mm | 6-48 | 10-60mm | 14-80mm |

| Rolling wheel diameter | 120-170MM | 120-170mm | 120-170mm | 175-220mm | 175-220mm |

| Max width of rolling wheel | 110MM | 110MM | 110MM | 150mm | 150mm |

| Spindle center distance | 120MM | 120MM | 120MM | 150-300mm | 150-300mm |

| Rolling wheel aperture | 54hole | 54hole | 54hole | 75hole | 75hole |

| Hydraulic power | 4kw | 2.2kw | 2.2kw | 3kw | 5.5kw |

| Main motivation | 4kw | 5.5kw | 7.5kw | 11kw | 11kw |

| Spindle speed | 36-78/min | 36-78/min | 36-78/min | 20-64/min | 20-64/min |

| Spindle tilt angle | ±5° | ±5° | ±5° | ±10° | ±10° |

| Thread length | No limited | No limited | No limited | No limited | No limited |

| Dimensions | 1.4*1.2*1.4m | 1.48*1.33*1.44m | 1.47*1.33*1.44m | 1.78*1.73*1.43m | 1.78*1.73*1.43m |

| Weight | 1100kg | 1700kg | 1800kg | 2000kg | 2600kg |

Hydraulic thread rolling machine application

Rebar wire rolling machine as the name suggests is the equipment that mainly handles steel bars. The main areas where people can apply it are building sites, bridges, tunnel construction, water conservancy projects, steel structure processing fields, and so on. In aerospace, machinery production, automobile manufacturing, and other fields, rebar rolling machines are applied wherever the construction of rebar connections involving reinforced concrete structures is concerned. One of the most common applications is in the field of construction engineering.

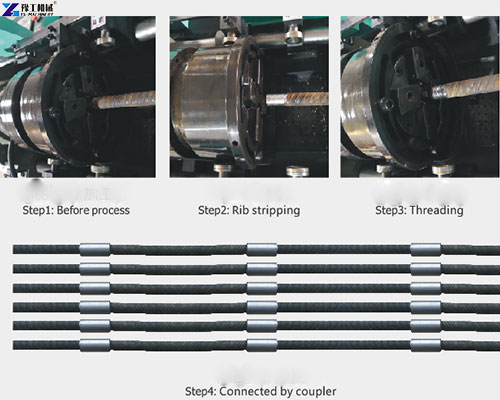

Steel bar after threading and rolling

The finished product of YG’s rebar thread rolling machine is standard, smooth, beautiful, and burr-free, as shown below:

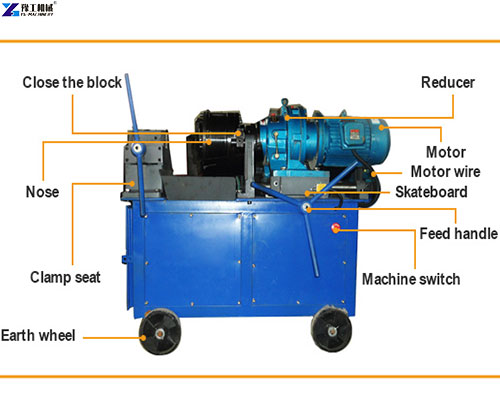

Structure of thread rolling machine for sale

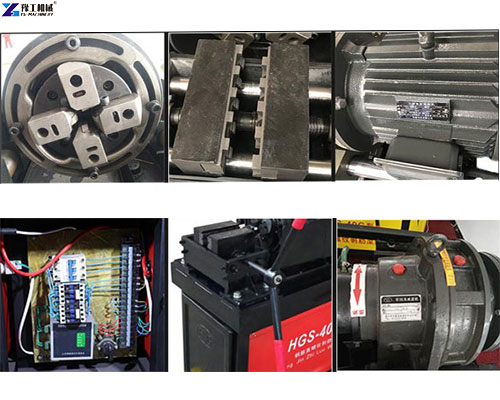

The thread rolling machine for sale mainly consists of a frame, clamping mechanism, feeding frame, reducer and rolling head, rib stripping device, cooling system, electrical system, and so on.

- Feeding device: It is used to feed the reinforcement material between the wire rolling wheels at a stable speed to ensure the smooth progress of the processing.

- Wire rolling wheel: It is the core part of the steel wire rolling machine, and its shape and specification directly determine the shape and specification of the final product.

- Discharge device: It is used to discharge the processed rebar products in time to ensure the smoothness of the production line.

- Control system: The steel bar rolling machine is usually equipped with a safe and reliable motor and hydraulic execution and control system, which can be controlled manually, semi-automatically, or fully automatically.

Automatic thread rolling machine working principle

In the process, the rebar material is fed between the rolling wheels, and through the rolling and squeezing of the wheels, the surface of the rebar is formed into the desired thread shape. The hydraulic thread rolling machine adopts advanced technology of rib stripping and rolling to process the straight threads of the connecting end of the reinforcing bar. The tensile strength of the rebar straight threads formed by its processing is increased by 20%-30%, fatigue strength by 40%-60%, and corrosion resistance by 50%-200%. The strength of the rebar connection is higher than that of the parent material of the rebar. This processing method not only ensures the accuracy and match of the thread but also improves the production efficiency and processing quality.

Detailed display of thread rolling machine for sale

The main components of YG’s rebar rolling machine are shown in the following figure:

Workflow of wire rolling machine

The workflow of the hydraulic thread rolling machine is relatively simple: start the machine, feed the steel, roll processing, shutdown inspection, cleaning, and maintenance of these steps.

Advantages of hydraulic thread rolling machine

- Reinforcing steel wire rolling machine can be a clamping to complete the stripping and rolling thread head processing. Processing tooth shape full, high dimensional accuracy.

- Can be processed positive buckle, or reverse buckle thread.

- The hydraulic thread rolling machine is simple to operate, compact structure, reliable work, with a unique tool automatic opening and closing mechanism. Steel bar can be clamped once to complete the thread processing, with high efficiency.

- Without cutting the base material of rebar, the strength of the wire head is higher than that of the base material.

- Wide range of adaptability, can be processed for the diameter of 16 ~ 40 ribbed steel bars.

- Adopts the cold rolling process of rolling wheel, and the processing of rebar wire head is “molded” with high precision and 100% qualification rate.

- It is convenient and quick to operate, and the ribbing and rolling of φ12-40mm HRB335 grade and HRB400 grade ribbed steel can be completed in one go with one wire rolling disk.

Precautions for the use of steel bar wire roller

Users need to pay attention to the wire roller to avoid the following conditions when using the wire roller:

1. The alignment of the wire rolling mold is not correct, the axial displacement of the rolled parts, and the threads are subjected to shear and extrusion of the two stresses.

2. The rolling thread blank size is not uniform, the surface is not clean, and there is wheel foam, oxide skin, and dirt.

3. The hardness of the rolled parts is not uniform (8.8-grade bolts should be 27 ~ 30HRC; 10.9 grade should be 35 ~ 37HRC), to prevent sometimes due mismanagement of the untempered high hardness (50 ~ 55HRC) of the quenched parts of the mixing and tempered parts, the hardness of which is similar to the hardness of the threaded edge of the roller wheel, resulting in the collapse of the edge.

4. Rolling without adding lubricant, resulting in dry friction, so that the tip of the temperature rises sharply to more than the tempering temperature of the wire roller, the teeth of the over-tempering were softened, the inverted teeth, stacked teeth failure.

5. The hydraulic thread rolling machine must be filled with lubricant before leaving the factory.

Rebar threading machine price

YG is a professional construction machinery manufacturer with 20 years of manufacturing experience. Our customers are located in many countries and regions. We can provide customers with a variety of construction machinery, such as steel bar straightening and cutting machines, steel upsetting machines, diamond rope saws, sleeves, hydraulic wall saws, rope saws, hammer for excavators, splitters, cotton candy vending machines, etc. As a manufacturing plant, we can provide customers with high-quality equipment and competitive prices. Regarding the rebar threading machine price, the prices of different models and accessories will vary, and we need to recommend them according to your specific needs. At present, our hydraulic thread rolling machines have been exported to Malaysia, Mexico, the United States, Singapore, Kuwait, Turkey, and other countries. After receiving the machines, customers are very satisfied. And hope to maintain a long-term cooperative relationship with us. Welcome to consult our products!