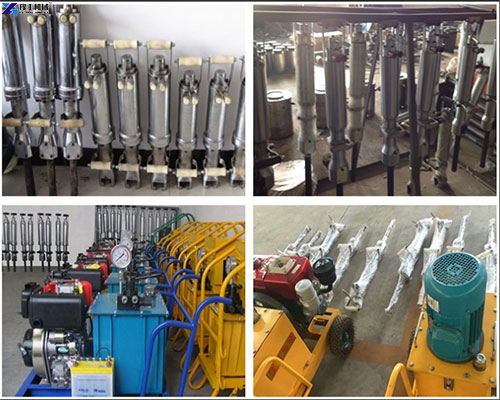

Hydraulic rock splitter for sale specially used to process rocks and concrete. Generally, people use it for mining and building demolition. It is a crushing equipment that works on the principle of hydraulics. It mainly consists of two parts: a hydraulic station and a splitting gun. They have different models and have different numbers of splitting guns. This requires you to decide according to your specific needs. YG provides splitters of various models and power, and we will recommend the appropriate machine configuration according to your needs.

Hydraulic Rock Splitter Machine Parameter

| Model | YG-250 | YG-350 | YG-450 |

| Power | Diesel Power Pack | ||

| Diesel Power Pack | Changchai 6hp or 8hp | ||

| Hydraulic Power Unit | Pressure Adjustable 10-60Mpa | ||

| Splitter Length (mm) | 1000 | 1100 | 1200 |

| Wedge Length (mm) | 250 | 350 | 450 |

| Wedge Weight (kg) | 30 | 36 | 43 |

| Piston Stroke (mm) | 90/220 | 90/220 | 90/220 |

| Drilling Depth (mm) | >500 | >700 | >900 |

| Drilling Diameter (mm) | 42 | 50 | 55 |

| Crack Width (mm) | 10-20 | 10-20 | 10-20 |

| Splitting Time (s) | 10-15 | 10-15 | 10-15 |

| Splitting Force (T) | 800 | 900 | 1000 |

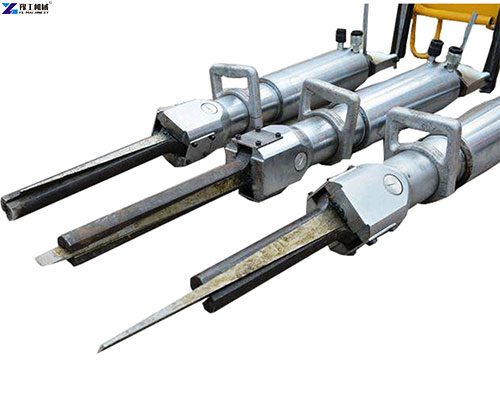

Hydraulic Rock Splitter Structure

The rock splitter mainly includes a hydraulic station, a power system, an oil pipeline, a splitting gun, a wedge, and a frame. His power is generally a diesel engine and an electric motor. Customers need to choose according to the power conditions in their area.

Accessories of Rock Splitter For Sale

Application Scenarios of Hydraulic Rock Concrete Splitter

The application of rock concrete splitter for sale is very wide. We can use the equipment both above and below the ground. The following are common applications:

- Infrastructure projects: We can use concrete splitters in foundation excavation, tunneling, subway construction, and other projects.

- Mining: Splitters split large pieces of ore into smaller blocks for subsequent processing and transportation. For the mining of precious stones, splitters can maintain the integrity of the stone.

- Concrete demolition: When renovating buildings or demolishing old buildings, splitters demolish concrete components such as walls, floors, bridges, etc.

- Agriculture and forestry: In the fields of agriculture and forestry, splitters can split tree roots, remove stones, and other operations, providing convenience for the growth of crops and the development of forestry resources.

- Emergency rescue and disaster management: After natural disasters such as earthquakes and landslides, splitters can quickly open rescue channels, remove obstacles, and improve rescue efficiency.

- Special projects: In airport runway maintenance and ancient building protection, splitters are favored for their static pressure-crushing characteristics.

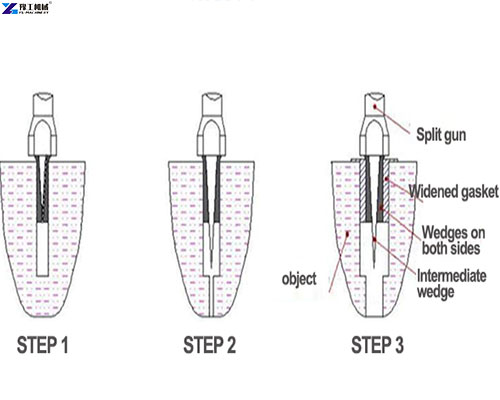

Working Principle of Hydraulic Splitter For Rock

The hydraulic splitter for rock uses the characteristics of high compressive strength and low tensile strength of rocks to work through the mechanical principles of wedge block groups.

When the splitter is working, the pump station outputs high-pressure oil to drive the oil cylinder, generating huge thrust. When the high-pressure oil output by the hydraulic station pushes the middle wedge of the splitting gun forward, the side wedges are pushed to both sides, and the object to be split is split in a predetermined direction in a very short time. This splitting method avoids the direct damage to the rock structure by external force impact in traditional mechanical crushing methods, thereby improving crushing efficiency and safety.

Advantages of Rock Splitter For Concrete

- Simple operation: The humanized design and durable structure of the rock splitter for sale ensure that its use is simple and easy to learn, and only one person is required to operate it. At the same time, the machine is easy to maintain and has a long service life.

- High efficiency: The rock splitter can cut different types of rocks quickly and efficiently, saving time and labor costs.

- High safety: Compared with traditional blasting methods, the rock splitter does not need to use explosives when cutting rocks, which greatly reduces the risk of explosions.

- Strong applicability: The rock concrete splitter is suitable for rocks of different types, hardness, and size, and has strong adaptability.

- Good environmental protection: The use of rock splitters will not produce toxic and polluting explosives, dust, etc., reducing environmental pollution and damage to the ecological environment.

- Small and easy to use: The hydraulic splitter is small in size and light in weight, and can be operated in all indoor and narrow places.

- High accuracy: Unlike most traditional demolition methods and equipment, the splitter can accurately determine the splitting direction in advance.

- Economical: Its operation and maintenance costs are very low; there is no need to take isolation or other time-consuming and expensive safety construction plan measures like blasting operations.

Precautions For The Use of Hydraulic Rock Splitter

- The rock drill drills about 40-42mm, and the drilling depth is not less than 50cm (otherwise the middle wedge is easy to break). The 350 type uses a 46 drill bit. After the hole is drilled, the hole must be cleaned, the slag is cleared, and the water is cleared. No. 46 hydraulic oil is used all year round.

- Before the hydraulic oil is returned, please do not shake the splitting gun. When pulling out the splitting gun, be careful not to shake it left and right, and do not use it as a crowbar (so as not to damage the splitting block).

- After use, please clean the splitting block and the middle wedge in time, do not use water to avoid rust. Before using the splitting gun, please use butter to apply the splitting block and the middle wedge to keep it lubricated.

- What is the reason for the bulging of the hydraulic oil pipe? Replace the oil pipe, one for pressurization and one for oil return.

- The reason why the pressure gauge is 20mpa is that the pressure gauge does not move when the motor is turned off, which means that the overflow valve is broken. The pressure gauge returns to zero, which means that the reversing valve seal is broken.

- The splitter cannot be pulled out because the split stone is too big and the gap is too small. It is stuck and needs to be broken open with a chisel.

Repair And Maintenance of Hydraulic Rock Concrete Splitter

Ensure the cleanliness and selection of hydraulic oil

A. First of all, be sure to ensure the cleanliness of the hydraulic oil. Before locking the quick connector, remove the surrounding sand and gravel.

B. When choosing hydraulic oil, follow the seasonal principle: in winter, it is advisable to use wear-resistant lubricants with lower viscosity, such as YC-N46, to adapt to low-temperature environments; in summer, wear-resistant lubricants with higher viscosity, such as YC-N68, should be selected to ensure lubrication effect under high temperature. At the same time, when the oil level drops to less than one-third of the length of the level gauge, hydraulic oil needs to be added in time.

Hydraulic oil should be replaced regularly

- Hydraulic oil may need to be replaced after working for about 400 hours due to deterioration, discoloration, or decreased viscosity to ensure the normal operation of the hydraulic system.

- Maintenance of the splitter when not in use:

A. When the hydraulic splitter for rock is out of use, all parts of the machine should be thoroughly cleaned to keep the parts clean and dust-free.

B. The hose should be thoroughly cleaned and properly hung to prevent premature aging.

C. To prevent rust, apply an appropriate amount of grease to the power head and wedge surface and seal it with plastic for protection.

Operation precautions

A. Avoid the splitter from being subjected to major external impact to avoid deformation of the oil cylinder and affecting its use.

B. During use, continuously check for oil leakage and deal with it immediately if found.

C. The working surfaces of the wedge and power head need to maintain sufficient high-pressure grease. If the working surface is scratched, it should be polished to smoothness in time.

D. It is strictly forbidden to use the gun head as a crowbar to prevent damage.

Maintenance and replacement of key components

A. The reversing valve model and structure on the oil station and the gun body must match, and the O-ring inside it is a consumable part, which should be checked regularly and replaced in time.

B. The overflow valve in the combination valve, especially its conical valve core and valve seat, needs special attention to maintenance. Once it is found to affect the working performance, it should be replaced immediately to ensure the stable operation of the system.

Customer Feedback For Concrete Splitter Machine

YG is an excellent manufacturer of splitters and drilling rigs. We have 19 years of production experience. We keep pace with the times and manufacture splitter equipment that is convenient for people to use and high-quality and durable. In addition to a rock concrete splitter for sale, we also have large splitters and splitting equipment for drilling and splittings, excavator rock saws, excavator crusher buckets, hydraulic pile crushers, metal shear for excavators, etc. This equipment can meet the needs of different customers for processing rocks or buildings of different sizes. Now our splitters have been sold to many countries and have been well received by customers.