High frequency wire saw is a more powerful cutting tool. It can reach depths that many cutting devices cannot reach. At the same time, the machine is lightweight and easy to move, and the remote control makes cutting easier. It can cut various rocks, concrete piles, concrete columns, beams, roads, docks, and other objects. We have wire saw equipment with different powers, and you can choose according to the power conditions in your country. Contact us and we will provide you with a high-quality diamond saw-cutting machine!

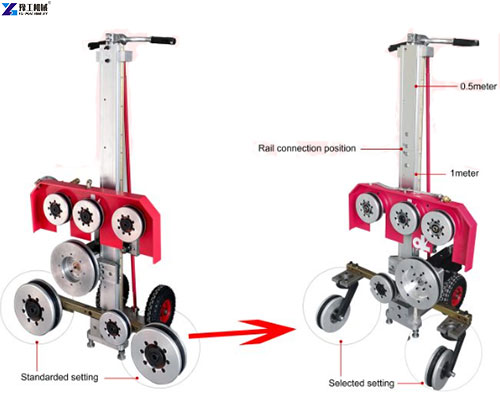

High Frequency Wire Saw Structure

The core of high frequency wire saw lies in its unique diamond rope, which can quickly and accurately penetrate concrete under high-frequency vibration. Combined with a powerful drive mechanism, wire saw rope, a sophisticated tracking system, an intelligent control unit, and an optional hydraulic system, it constitutes an efficient and flexible cutting system. These components work together to ensure that every cut can achieve the established accuracy and depth.

5 Concrete Wire Saw Machine Advantages

- Precise cutting: High-frequency wire saws can achieve smooth and accurate cutting of concrete materials, greatly reducing material waste.

- Efficiency: Compared with traditional methods, diamond wire saws cut faster and significantly shorten project cycles.

- Environmental protection and safety: Reduces dust generation, improves workplace safety, and reduces negative impacts on the environment.

- Versatility: Suitable for cutting various concrete structures, from large beams to complex sculptures, the device can handle them.

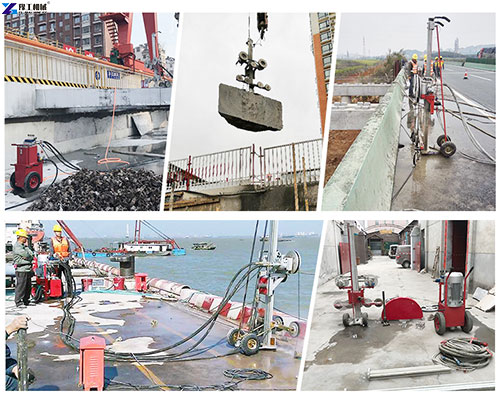

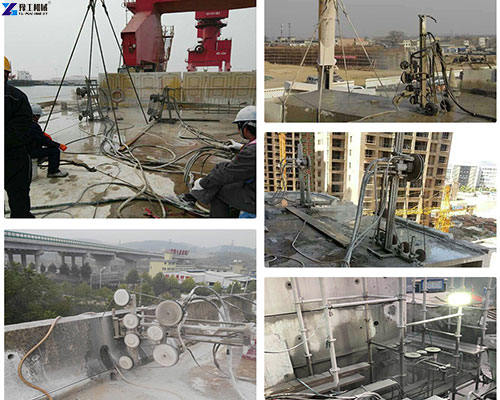

Application Areas of Diamond Saw Cutting Machine

- Building demolition and renovation: When demolishing old buildings or renovating structures, a high frequency wire saw is an ideal choice for cutting concrete walls, beams, and columns.

- Stone processing: Although mainly used for concrete, a diamond saw-cutting machine is also suitable for stone processing, providing the possibility of fine cutting of materials such as marble and granite.

- Bridge and tunnel maintenance: In bridge reinforcement and tunnel repair projects, these machines can accurately cut concrete to ensure the smooth progress of repair work.

Working Principle of High Frequency Wire Saws

The working principle of high frequency wire saws is based on the combination of high-frequency vibration and diamond grinding technology. Under high-speed vibration, the diamond rope continuously wears the concrete material with diamond particles on it to form a clean cut. Through the precision-designed tracking system and control unit, the operator can easily adjust the cutting path and depth for precise control.

High Frequency Wire Saw Machine Price

Considering the diversity and professionalism of wire saws for concrete, their price range is relatively wide. From entry-level models suitable for small projects to fully automatic systems that meet industrial-level needs, prices range from tens of thousands of dollars to hundreds of thousands of dollars. However, considering its significant advantages in improving efficiency, reducing waste, and ensuring safety, investing in a high-quality high-frequency wire saw is undoubtedly a wise decision.

High-Quality Diamond Saw Cutting Machine from YG

The high-frequency diamond saw cutting machine provided by YG has significantly improved cutting efficiency while maintaining the smoothness and precision of the cutting surface, whether it is hard stone, concrete, or other composite materials, it can easily cope with it.

YG Machinery is committed to providing customers with high-quality wire saw equipment. There are also different types of electric wire saws, hydraulic wire saws, crawler wire saws, and mining wire saws, each of which has its characteristics. YG will recommend the appropriate wire saw model according to the specific needs of customers. We also produce related cutting equipment such as hydraulic wall saws, rock splitters, drilling and splitting machines, etc. We have exported this equipment to many countries, such as Australia, Singapore, Saudi Arabia, Brunei, Israel, Brazil, Madagascar, and the United States, and have maintained long-term cooperative relations. If you need it, please contact us and we will provide you with detailed product information!