The high frequency wall saw is a new type of equipment specializing in cutting building walls, floors, ceilings, rocks, ceramics, and brick walls. It can be widely used in building renovation, earthwork quality inspection, water, electricity, heat and gas system installation, railroad reinforcement, bridge and tunnel installation, and other installation work. Due to its powerful working effect and super cost-effective, it has gained the favor of many customers. Besides wall saw equipment, we also have professional splitter equipment for dealing with rock and large concrete.

High Frequency Wall Saw Technical Parameter

| Saw blade | |

| Max. cutting depth | 510mm |

| Max. saw blade | φ1200mm |

| Saw blade fixing(flush cuts) | 6 countersunk head screws,110mm graduated circle. |

| Electric motor(water cooling & high frequency) | |

| Max. output power | 16kw |

| IP classification | IP 67 |

| Weight | |

| Wall saw 105DM Incl. feed electric motor | 27kg |

| Electric main motor 16kw | 18kg |

| Control unit | |

| Voltage | 380-460V(single phase available) |

| Frequency | 50Hz/60Hz |

| Weight | 19kg |

| Wireless control | 2kg |

Usage of Wall Mounted Concrete Saw

The high frequency wall saw is widely used in building project remodeling, demolition, and reinforcement construction. The most commonly used are operations such as opening doors, windows, and vents, and cutting off reinforced concrete beams and columns on walls; they can also be used for cutting and remodeling floor slabs, bridges, and other structures. In addition, high-frequency wall saws can also be used in stone processing, metal cutting, and other fields.

High-Frequency Wall Mounted Concrete Saw Structure

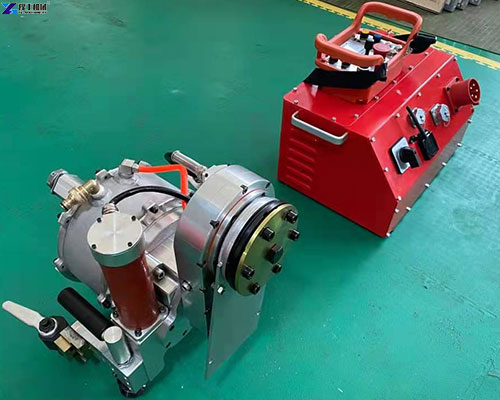

A general high-frequency wall mounted concrete saw will contain the following parts: 1 head, 3 meters of track, 1 pump station, 2 cable lines, 1 saw cover, 1 saw blade, 1 wireless remote control, and 1 toolbox.

Among them, our wireless remote control can control the range within 30 meters, visualization intelligent control, safe and reliable. The high-frequency electric box can be freely switched between 220V and 380V, adapting to more cutting conditions. Users can apply our equipment more safely and flexibly. You are welcome to inquire, we will recommend the right model of high frequency wall saw for you!

Characteristics of Concrete Wall Cutting Saw

- High efficiency and precision: the cutting efficiency of high-frequency wall saw is much higher than that of traditional cutting tools, and due to the high vibration frequency and fast movement of the saw blade, it can realize millimeter-level cutting precision.

- Low noise: due to the characteristics of high-frequency vibration, high-frequency wall saws are lighter and smoother when working, which helps to reduce noise pollution during operation.

- Strong adaptability: high-frequency wall saws are lightweight and more powerful, and can be applied in a variety of occasions.

- Energy saving and environmental protection: the working principle of high-frequency wall saw has the advantages of low energy consumption and environmental protection. Through precise cutting, it can also reduce the waste rate and material loss.

- Widely applicable: high-frequency wall saws are not only suitable for building demolition and wall cutting but also widely used for high-precision cutting in the field of wood processing (e.g. furniture, flooring, doors and windows, etc.).

Working Principle of High-Frequency Concrete Wall Cutting Machine

The working principle of high-frequency wall saw is to convert high-frequency electric energy into vibration energy. Then transmit the vibration energy to the cutting surface for cutting through the saw blade. Its vibration components are the electromagnetic coil and oscillator. When the power supply is energized, the current passes through the electromagnetic coil to generate an electromagnetic field. This in turn causes the magnetic core on the oscillator to generate high-frequency vibration.

The saw blade is fixed on the vibration part of the high-frequency high-frequency wall saw. When the vibration part operates, the saw blade produces rapid up-and-down movement due to vibration, thus realizing the purpose of rapid cutting.

Steps of Using a Wall Sawing Machine

- Install the wall saw on a stable surface.

- Attach the diamond blade to the saw.

- Mark the desired cutting path on the material.

- Adjust the depth of the saw blade to the desired depth.

- Start the saw and make a shallow cut along the marked cut path.

- Repeat steps 4 and 5 until the desired depth is reached.

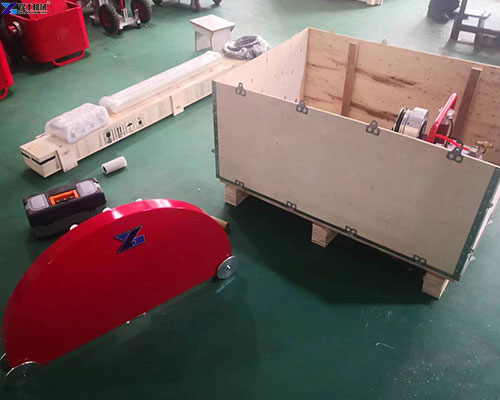

Concrete Cutting Sawing Machines Exported to Australia

Some time ago, we exported a wall saw to Australia. The Australian customer is a professional building renovator and their team need a new wall saw to get the job started. The customer came in from our website and got our contact information. Our sales manager immediately spoke with the customer. Based on the customer’s specific needs, our sales manager recommended a standard HF wall saw. At the same time to provide customers with a detailed equipment quotation, the customer after consideration decided to buy from us. In addition to high-frequency wall saws, we also produce hydraulic wall saws and electric wall saws. There are also related hydraulic rope saws, tracked wire saws, high-frequency wire saws, hydraulic rock splitters, log splitters, branch shredder machines, and water drilling equipment, etc. Contact us now for more information!