GRC spraying machine, full name Glassfiber Reinforced Concrete (GRC) spraying machine. It is a kind of high-efficiency spraying equipment used for building exterior wall decoration, interior decoration landscaping projects, etc. GRFC spray machine is sprayed by a high-pressure screw pump with a mixture of raw materials such as glass fiber and sand into a mist to form a strong building material with a smooth surface. It mixes cement, sand, glass fiber, and other raw materials through high-pressure screw pumps and then sprays them into the mist to form building materials with strong textures and smooth surfaces. Click the button and we will provide you with a detailed quote!

Parameters of GRC Spraying Machine

| Model | YG-Y80 GRC shotcrete machine (screw type) | YG-Y100 GRC Spray machine (plunger type) |

| Power supply | 380V 50HZ (three-phase) | 380V 50HZ (three-phase) |

| Production efficiency | 300-400㎡/h | 300-600㎡/h |

| Working air pressure | 0.6-0.8mpa | 0.6-0.8mpa |

| Capacity | 50L | 60L |

| Conveying capacity | 300-1600kg/h | 300-1600kg/h |

| Working area | 4.0 meters (horizontal arm radius) | 4.5 meters (horizontal arm radius) |

| Speed | 40-200r/min | 20-280r/min |

| Power | 2.2-3.0KW stepless speed regulating motor | 1.5-2.2KW stepless speed regulating motor |

| Dimension | 1400*1000*2200mm | 1300*1000*2200mm |

| Equipment weight | 220kg | 300kg |

Application Scope of GRC Equipment

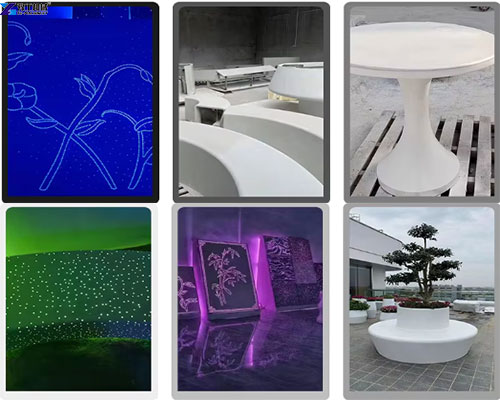

We widely use the GRC spraying machine in building exterior wall decoration, interior decoration spraying (such as putty powder, latex paint, real stone paint, etc.), fireproof and waterproof material spraying, heat preservation material spraying, relief crafts paint spraying as well as small villas, clubs, bridges, wigwams, dams, he-guardrail, etc. spraying and spraying slurry. Because it’s spraying out of the component surface quality is smooth and meticulous, internal density, quality, and density performance is good, compressive and tensile ability. So it is very suitable for the production of GRC European-style components, GRG products, and so on.

Specific Application Scenes of the GRC Machine

- Classical style building. The architectural decorative components made of GRC panels have realistic and delicate modeling and strong expressive power, which is a very ideal building material for shaping classical style. It has become the mainstream material for classical-style buildings in Europe and America.

- Modern architecture. Due to their lightweight, simple installation, and high strength, we can prefabricate GRC architectural panels in large quantities in factories to shorten the construction period. And people can easily mold GRC architectural panels into various shapes, with strong surface textures. It has strong architectural expressiveness as an enclosing component of modern buildings.

- Landscaping: People also use the GRC spraying machine in a large number of landscaping designs, to build a variety of exquisite architectural vignettes, fountains, flower pots, lounge chairs, and other decorations.

- Repair of monuments: GRC components can faithfully reproduce the original building components that have suffered damage and are in line with international principles for the restoration and protection of cultural relics and buildings.

- Interior decoration. In addition, we can also use the GRC equipment in interior design, such as decorative tape, fireplaces, etc. GRC in foreign countries, especially in Europe and the United States developed countries have been greatly developed.

Structure of GRFC Spray Machine

The machine has a reasonable design, compact structure, and small volume, easy to disassemble and maintain. GRC spraying machine mainly includes a machine bracket and universal moving table, 4.5m radius horizontal suspension arm, fiberglass filament bracket, stepless speed control motor and supporting power distribution cabinet, precision pneumatic system (including high-pressure air hose and quick connector, mortar hose and quick connector, pneumatic vibration, etc.) and so on.

4 Features of the GRC Fiberglass Spray Machine

- High construction efficiency. Airless spraying mechanized construction, the efficiency is about 10 times the traditional manual roller brush efficiency.

- The wall coating is even fine and smooth with good texture. The paint is atomized into fine particles under high pressure, evenly distributed on the wall surface, forming a smooth, smooth, dense coating on the wall.

- Strong adhesion of the coating, prolonging the coating life. Coating particles penetrate into the wall under high pressure, which enhances the mechanical biting force between coating particles and the wall. It makes the coating more dense and the service life of the coating longer.

- The high utilization rate of paint. Compared with brush coating and roller coating, airless spraying does not need to be dipped during on-site construction. So it avoids the waste of paint.

GRC / GFRC Spray Machine Manufacturer-YG Equipment

YG is a professional manufacturer of construction spraying equipment. We offer mortar sprayers, wall plaster machines, concrete pumps, concrete mixer conveyor pumps, concrete mixers, polyurethane sprayers, polyurethane foam machines, hydraulic lift platforms, construction telehandlers, concrete curb extruders, and so on. With advanced production technology and rich industry experience, we are committed to providing customers with efficient, stable, and easy-to-operate GRC spraying solutions. Colleagues we focus on technological innovation and quality control, customer demand-oriented, and constantly optimize product performance. Fill in the message box below, tell us your specific needs, and YG will provide you with a detailed quotation!