A full hydraulic crawler core drilling rig is a professional geological coring equipment. The hydraulic core drilling rig produced by YG has the features of an advanced structure, fast feed speed, and low failure rate. It has a wide range of applications. It is mainly used in the fields of geological engineering, infrastructure engineering, tunneling, and water well drilling. Hydraulic drive gives the core drilling rig stable operation and strong power. Our hydraulic core drilling rigs are of good quality, have strong power, and are reasonably priced. Please contact us for more information!

Full hydraulic crawler core drilling rig parameters

| Model | YGX-400 | YGX-600 | YGX-800 | YGX-1000 |

| Drilling Depth(M) | 180-400-500 | 200-600-650 | 400-800-1000 | 500-1000-1100 |

| Rated pressure(MPA) | 21 | 21 | 25 | 28 |

| Rated Flow(L/min) | 168 | 192 | 260 | 300 |

| Heat Dissipation Mode | Air cooling+water cooling | |||

| Engine Brand | Yuchai | Yuchai | Yuchai | Cummins |

| Rated power/speed | 78kW/ 2400r/min | 92kW/ 2400r/min | 92kW/ 2400r/min | 154kW/2400r/min |

| Drilling Angle(°) | 0-90 | 45-90 | 45-90 | 45-90 |

| Lifting Force(T) | 12 | 16 | 24 | 30 |

| Feed Force(T) | 6 | 8 | 12 | 15 |

| Hydraulic Mud pump flow | 30-90(L/min) | 30-90(L/min) | 90-180(L/min) | 90-180(L/min) |

| Hydraulic Mud pump power | 4-7(MPA) | 4-7(MPA) | 4-7(MPA) | 4-7(MPA) |

| Dimension | 4000*1900*1800mm | 4000*2000*1800mm | 5500*2100*2000mm | 6000*2200*2400mm |

| Weight | 4.3T | 4.5/5.5T | 6.5T | 7.5T |

Full hydraulic core drilling rig application range

The hydraulic core drilling rigs have a wide range of applications. Its application fields include geological exploration, resource development and utilization, foundation engineering, water conservancy, and hydropower and tunnel strip engineering surveys. In addition to these common applications, it can also used in the fields of water well drilling, mining construction, engineering frontline rescue construction, and so on.

Fully hydraulic core drilling rigs are crawler type. In addition to moving in flat terrain, it is also suitable for core drilling surveys in mountainous, forested, and plateau areas.

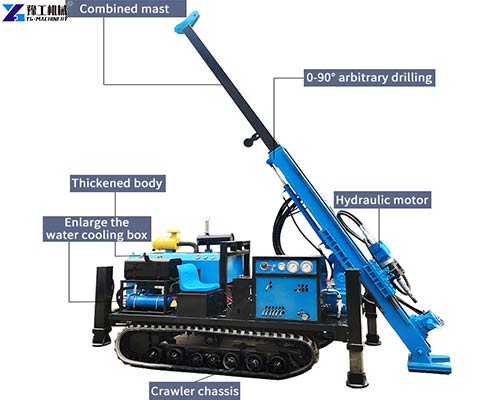

Fully hydraulic core drilling machine structure

The main components of the fully hydraulic core drilling rig include crawler chassis, welded frame, skid frame, slewing mechanism, propulsion part, hydraulic gripper, leveling jack, winch, manipulator, hydraulic system, power system, etc. All the components and configurations of YG’s fully hydraulic core drilling rig are of high quality and durability. The whole fully hydraulic core drilling machine is reasonable in structure, wear-resistant, and durable, with long service life. His bloat is low and we don’t need to service it very often. Welcome you to consult our full hydraulic crawler core drilling rig!

6 features of core drilling rigs for sale

- The power head moves along the mast with good guidance. This can increase the pure drilling time. And because the drilling process is continuous, a full hydraulic crawler core drilling rig can reduce the probability of accidents in the hole.

- Users can adjust the drilling angle. And we can move the machine easily and relocate it.

- The power head and the orifice gripper can realize the unscrewing and un-screwing of the pipe, which makes the structure of the drilling rig more simple.

- The hydraulic power supply is an easy and simple operation, which reduces the operator’s labor intensity and the number of operators.

- The core drilling rigs for sale have an overload protection function. And the rotary and feed can realize step-less speed regulation. So we can control the drilling pressure precisely. We can adjust it according to different drilling scenarios.

- The transmission system is simple, the whole machine is light in weight, and it is easy to install and dismantle.

Precautions for the use of core drilling machine for mining

- Pay attention to checking the oil circuit and air circuits at any time. Check the oil circuit, air circuit, and the connection status of screws, nuts, and joints of each part.

- It is strictly forbidden to reverse when drilling, so as to avoid the drilling rod from buckling.

- When the hydraulic oil is added to the oil tank. We should make sure the oil and the oil tank are clean and clear.

- After the work is completed, the four support legs are raised to get the tracked chassis off the ground. Clean the mud and sand on the traveling chassis before walking.

- When the drilling rig is traveling, the drilling frame must be leveled to prevent damage to the boom cylinders and joints.

- Check the chain tightness of the crawler chassis every day, which can be adjusted by adding grease to the tightening cylinder inside the chassis.

Full hydraulic crawler core drilling rig from YG

YG has various types of hydraulic core drilling rigs, such as FD400, FD500FD, 600, FD800, FD1000, and so on. They have different power and can realize different drilling depths, customers need to choose the right model according to their own situation. Due to the high efficiency and good quality of our equipment, it has a long service life. By now our fully hydraulic core drilling rigs have been sold to many countries, such as Indonesia, Bulgaria, Cameroon, Solomon Islands, Ecuador, Argentina, Australia, Togo, Papua New Guinea, Philippines, and so on. As a professional drilling rig manufacturer, we not only produce hydraulic core drilling rigs. But also water well-drilling rigs, DTH drilling rigs, crawler water well drilling rigs, towed water well-drilling rigs, rotary drilling rigs, and other drilling rigs. We provide high-quality and low-priced equipment, welcome to consult with us!