Floor bead blaster is widely used in concrete roughening, marking line cleaning, ship deck rust removal, and other industries. The cleaned road surface is uniformly rough and improves the adhesive strength of the waterproof layer and the concrete base. It is also able to fully expose the cracks in the concrete and help people repair the pavement in time. The road surface shot blasting machine comes with a dust collector, which can recycle the generated debris and dust in time. The treated pavement is clean and rough. Contact us to get a floor shot blaster free quote!

Floor Bead Blaster Parameters

| Model | YG-270(Single) | YG550/600(Double) | YG-850(Double) | |

| Shot Blasting Wheel Diameter | 200mm | |||

| Working width | 270 mm | 550/600 mm | 800 mm | |

| Walking speed | 0.5~20 m/min | 0.5~33 m/min | ||

| Concrete surface cleaning efficiency | ≥180 m2/h | ≥400 m2/h | ≥600 m2/h | |

| Steel plate surface cleaning efficiency | 15-25 m2/h | 75-100 m2/h | 100-160 m2/h | |

| Dust connection pipe diameter | 120 mm | 150 mm | ||

| Suggest the diameter of steel balls | 1.2-1.5 mm | 1.5-1.8 mm | ||

| Steel pill consumption | 10 g/m2 | |||

| Supporting dust collector | Seven-core automatic backflush vacuum cleaner | Eight-core automatic backflush vacuum cleaner | ||

| Shot wheel motor | Power consumption | 11 kW | 11*2 kW | 15*2 kW |

| Input Current | ≤ 15 A | ≤ 22*2 A | ≤ 28*2 A | |

| Walking motor | Power consumption | 0.5 kW | 1.5 kW | |

| Input Current | 1 A | 3 A | ||

| Size (mm) | 1000*300*1100 | 1950*720/775*1400 | 1950*1020*1550 | |

| Weight | 150 kg | 570 kg | 700kg | |

| Power connection requirements | 400V, 50Hz, 100A, CEE socket | |||

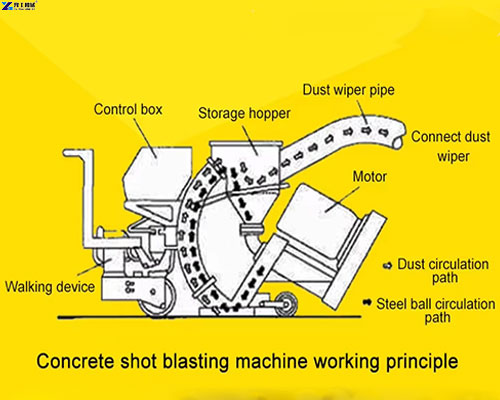

Bead Blaster Floor Machine Structure

There are two main components of a floor bead blaster. And the main body of the machine and the back suction dust collector. Dust extraction ducting (120mm for 270, 200mm for 550, and 250mm for 850) and cables will connect these two parts.

The other parts are mainly the shot blasting motor, electric control box, traveling motor, directional bushing, shot blasting wheel, storage material feeding hopper, filtration system, dust storage system, and so on.

Main Accessories of Shot Blasting Machine

- Blasting wheel, directional sleeve, hair row, rear pallet, middle guard plate, top guard plate, side guard plate, combined plate, spindle, large pulley, small pulley, motor belt, fan belt, bearings, seals, quick plug, aviation plug, filter cartridges, walking wheels, walking wheel, walking key, abrasive valve control line, speed reducer. These are the parts of the bead blaster floor machine, before packing we will place them reasonably and check them carefully to ensure that the machine is intact.

- Main wearing parts: directional bushing and blast wheel, top guard, and side guard.

Application of Concrete Floor Bead Blaster

- Road mobile shot blasting machines can be widely used in steel bridge decks, steel plate surfaces, ship steel surfaces, large steel structure planes. And the bottom of the tank steel surface anti-corrosion pretreatment.

- Highway bridges, urban viaducts, special roads, concrete base pavement layer before the construction of the treatment, and other fields.

Working Conditions of Floor Shot Blasting Machine

- The surface of the working surface. The unevenness of the working surface <10mm; no water and relatively dry; slope <25 °

- The machine’s working environment temperature. Is -20 ℃ ~ 60 ℃; the steel surface temperature is greater than the dew point of more than 3 ℃.

- About humidity. A steel surface shot blasting relative humidity of not more than 90%. b, concrete shot blasting relative humidity of not more than 95%.

- Altitude: 0 ~ 3000m; shall not be operated in rain or snow.

YG’s Concrete Blasting Machine

YG is committed to providing customers with high-quality road surface treatment equipment. Our floor bead blasters are high quality, efficient, and very durable. These features help you save a lot of money on maintenance and usage. We have professional technical and sales staff who can recommend the right model of equipment for you, the installation, and usage. As well as the later maintenance and problem-solving. YG will provide a one-stop service, you can contact us anytime. We also produce extruded curb machines, concrete pumps, concrete mixers, polyurethane sprayers, concrete mixer and pumps, snow removers, snowmaking machines, and so on. Don’t hesitate to contact us to get the lowest price!