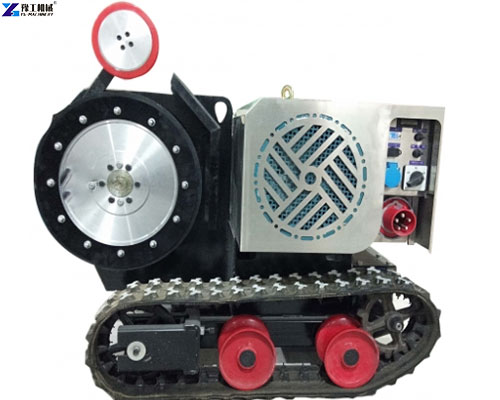

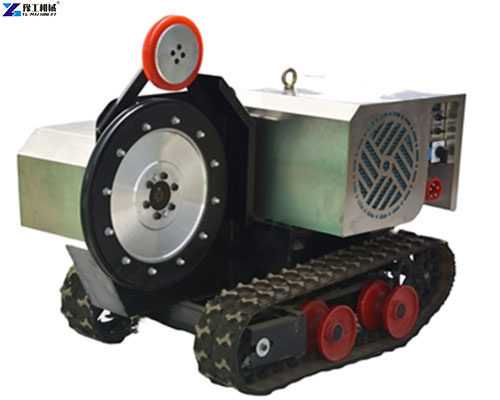

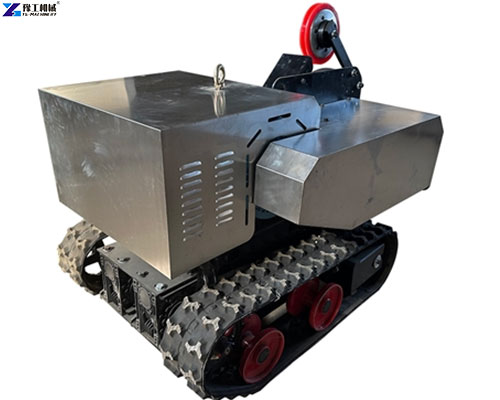

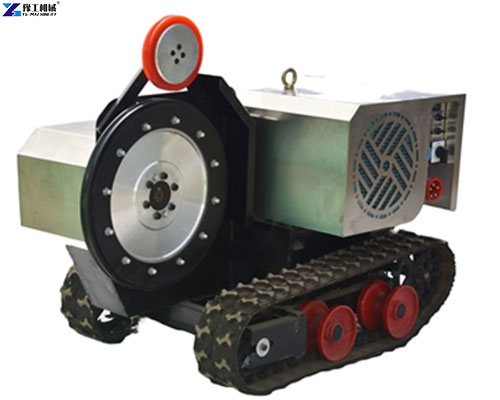

The track electric wire saw machine is cutting equipment that can move by itself. The equipment works with a diamond rope. It can cut metal and concrete buildings. The remote control system makes the operation easier and safer. It can flexibly cope with the complex environment of various construction sites. The crawler rope saw has attracted more and more people to apply it with its excellent cutting performance, flexible mobility, and environmentally friendly construction method. Click to get a free quote for the equipment!

Track Electric Wire Saw Machine Parameters

| Model | YG-37HT-6P | YG-45HT-6P | YG-55HT-6P |

| Main Motor Power | 37KW-6P(50HP) | 45KW-6P(60HP) | 55KW-6P(75HP) |

| Flywheel Diameter | φ800mm | φ800mm | φ800mm |

| Wire Saw Speed | 0-40m/s | 0-40m/s | 0-40m/s |

| Max. Wire Saw Length | 20-60m | 20-80m | 20-100m |

| Walking Motor Power | 0.75KW(1HP) | 0.75KW(1HP) | 0.75KW(1HP) |

| Rotation Angle(Electric) | 360° | 360° | 360° |

| Walking Speed of Machine | 0-60m/h | 0-60m/h | 0-90m/h |

| Rail Length | 7.3m | 7.3m | 7.3m |

| Allowed Working Temperature | -15~+40℃ | -15~+40℃ | -15~+40℃ |

| Crawler Power | 42KW(56HP) | 42KW(56HP) | 42KW(56HP) |

| Dimension: L*W*H | 7300*2380*2150mm | 7300*2380*2150mm | 7300*2380*2150mm |

| Net Weight | 7T | 7.3T | 7.5T |

Application of Portable Diamond Wire Saw

Track electric wire saw machines can handle most reinforced concrete buildings. There are walls, beams, columns, foundations, brick, stone, and metal walls. It is an essential cutting equipment in building demolition, water conservancy projects, road construction, urban construction, and pipeline laying!

5 Features of Wire Saw for Concrete

- It is building demolition. It can mainly demolish large concrete structures without affecting the surrounding structures, such as bridges and some components of tall buildings.

- Tunnel construction. Electric wire saw machines can assist in tunnel excavation and trimming work.

- High cutting precision. It can realize high-precision straight lines and curve cutting. And has high lightness and a flexible cutting angle.

- Low noise and vibration. Crawler rope saws work with low noise, reducing the impact on the surrounding environment and personnel.

- Good safety. The equipment is operated remotely, so the operator can stay away from the cutting site to ensure their safety.

Diamond Wire Saw for Concrete Use Precautions

- For correct operation. The operator must be trained and familiar with the operation of the equipment before using the electric rope saw machine.

- Operate in strict accordance with the operating procedures. Before starting the equipment, check whether the components are firmly installed, especially the connection parts of the rope saw.

- Make sure the equipment is in good working condition before starting.

- During the cutting process, keep the feed speed even and avoid being too fast or too slow.

- Stop feeding immediately when encountering excessively hard materials or obstacles. Check the condition of the electric wire saw machine to avoid damage to the rope saw caused by forced cutting.

Electric Wire Saw Machine from YG

YG is a professional manufacturer of rope saw equipment. We also produce electric wire saw machines, mining rope saws, hydraulic wire saws, hydraulic wall saws, electric wall saws, high-frequency wall saws, hydraulic rock concrete splitters, log splitters, branch shredder machines, and other equipment. Tracked rope saws are based on electric rope saws with the addition of tracks. It can also be operated by remote control, which is safer and more reliable. Self-propelled tracks can also help the equipment to work in a narrower work site. Click to get the factory price of the machine!