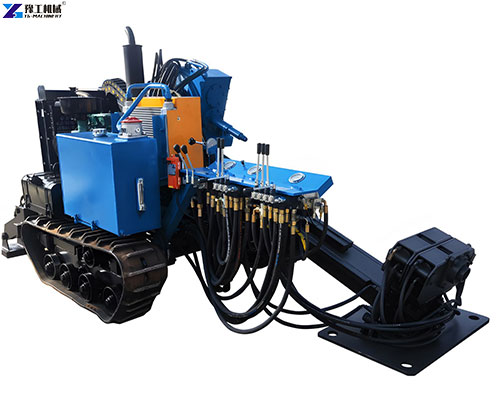

Directional drilling equipment is a kind of construction machinery for laying underground utilities. It can unfold laying pipes and cables without excavating the ground surface. This machine is widely used in water supply, electric power, telecommunication, natural gas, gas, oil, and other flexible pipeline laying construction. It is suitable for sandy soil, clay, and other ground conditions but unsuitable for high water tables and pebble strata. Horizontal directional drilling is characterized by fast construction speed, low construction precision, low cost, etc. YG provides you with high-quality horizontal directional drilling, consult us for more information!

HDD Machine for Sale Technical Parameter

| Model | YG200 |

| Main engine part | 48kw 65HP |

| Host width | 1.6m |

| Host length | 3.8m |

| Host height | 1.8m |

| Travel system | remote control, crawler walking |

| Ground drive system | 2KM/hour |

| maximum working distance | 200 Meter |

| Drill pipe diameter | ≤500mm |

| Incidence angle | 10-22 degrees |

| Departure angle | 20 degrees |

| Host weight | 2.3t |

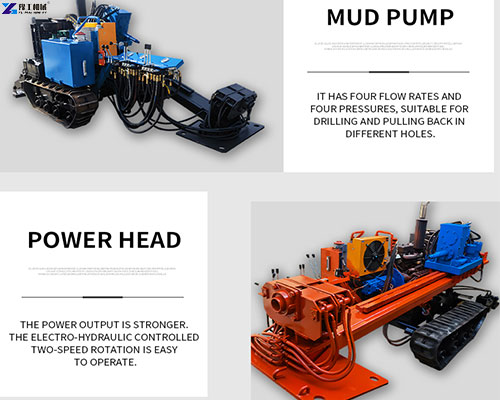

| Water injection system | three-cylinder mud pump |

| Pilot bit | bit diameter 100mm |

| Drill pipe length | 2 meters |

| Climbing ability | 35 degrees |

| Transfer case | 8tons |

| Reducer protection head | 2 |

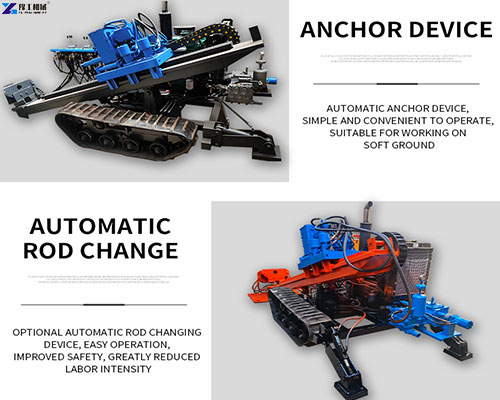

| Ground Anchor | 2 |

| Reducer protection head | 2 |

| Ground Anchor | 2 |

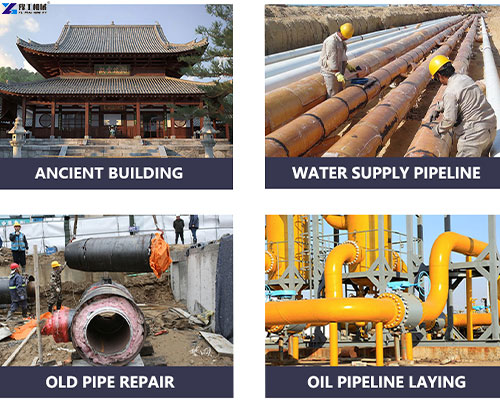

Directional Drilling Equipment Application

Horizontal directional drilling is suitable for steel pipes and PE pipes with pipe diameters φ300~φ1200mm, and the maximum length of pipe laying can reach 1500m, which is adapted to a variety of soil conditions ranging from soft soil to hard rock, and has a broad application prospect.

1. Application field: this technology has been widely used in the construction of flexible pipelines laying in water supply, electric power, telecommunication, natural gas, gas, oil, and so on.

2. Geological conditions of application: it is suitable for sandy soil, clay, and other ground conditions, unsuitable for high water table and pebble strata, most of the non-hard rock areas in China can be constructed.

Ditch Witch Drill for Sale Structure

Horizontal directional drilling mainly consists of five components: a drilling rig system, power system, direction control system, mud system, drilling tools, and auxiliary equipment.

1. The drilling rig system: it consists of a drilling rig mainframe, turntable, and so on.

2. Power system: it consists of a hydraulic power source and generator. The power source is to provide high-pressure hydraulic oil for the drilling system as the power of the drilling machine.

3. Direction control system: the direction control system is a directional tool to guide the drill bit to drill correctly by monitoring and controlling the specific position of the drill bit in the ground and other parameters through the computer.

4. Mud system: the mud system consists of mud mixing and stirring tanks, mud pumps, and mud pipelines, which provide the drilling rig system with mud suitable for drilling conditions.

5. Drilling tools and auxiliary tools: various tools used in drilling and reaming in the drilling rig. Drilling tools mainly include drill pipes, drill bits, mud motors, reamers, cutting knives, and other tools. Auxiliary tools include rings, swivel joints and drag heads of various pipe diameters.

Directional Drilling Machine for Sale Working Principle

A horizontal directional drilling rig connects the drill pipe through the drill bit and enters the underground from the ground into the pit at a certain angle under the action of the engine system. The machine then drills a pilot hole in the ground with a given pipeline path. Keep working until the hole size meets the requirement of pipeline back dragging. Then connect the single-action joint of the reamer with the pull-back joint of the completed pipeline. Finally, the pipe is towed back from the excavation pit to the W25-W26 position, and the construction is completed.

Directional Drilling Machine Features

1. No obstruction to traffic, no damage to road surface.

2. High precision, can steer, adjust depth at any time, and can bypass obstacles.

3. Urban construction through three meters a bit, through the river up to 6-18 meters.

4. Short construction period, fewer construction workers, more safety, lower cost.

5. When the pipeline is buried 6-18 meters, the oxygen and other corrosive substances inside the ground are very little, so it plays the function of natural anti-corrosion and heat preservation, which can guarantee the pipeline runs for a longer time.

HDD Drill Rig from YG

As a professional manufacturer of drilling rigs, YG’s drilling rigs are of high quality and low price and have gained the favor of many customers. Our small horizontal directional drilling (HDD machine) rigs are made of high-quality materials and advanced manufacturing technology to ensure the durability, stability, and reliability of the equipment. Meanwhile, the equipment has a precise control system and positioning technology, which can improve drilling accuracy and efficiency. Our excellent sales managers will provide customized equipment and services according to the specific needs of customers to meet the requirements of different projects. We also produce water well drilling rigs, DTH drilling rigs, solar pile drivers, fully hydraulic core drilling rigs, rotary drilling rigs, guardrail pile drivers, water well drilling rigs, core drilling machines, and rock concrete splitters. You are welcome to consult us to get a quote for your machine!