A crawler wire saw machine, as the name implies, is a wire saw device that can be moved by crawler tracks. It can mainly handle hard and brittle materials such as mines, stones, concrete, etc. Crawler wire saws are safe to operate, easy to move, and have good cutting effects, making them the first choice of many customers. YG has exported crawler wire saws to Saudi Arabia, Australia, Singapore, Brazil, the Philippines, the United States, etc. Contact us for a quote.

High Frequency Wall Saw Technical Parameter

| Model | YG-37HT-6P | YG-45HT-6P | YG-55HT-6P |

| Main Motor Power | 37KW-6P(50HP) | 45KW-6P(60HP) | 55KW-6P(75HP) |

| Flywheel Diameter | φ800mm | φ800mm | φ800mm |

| Wire Saw Speed | 0-40m/s | 0-40m/s | 0-40m/s |

| Max. Wire Saw Length | 20-60m | 20-80m | 20-100m |

| Walking Motor Power | 0.75KW(1HP) | 0.75KW(1HP) | 0.75KW(1HP) |

| Rotation Angle(Electric) | 360° | 360° | 360° |

| Walking Speed of Machine | 0-60m/h | 0-60m/h | 0-90m/h |

| Rail Length | 7.3m | 7.3m | 7.3m |

| Allowed Working Temperature | -15~+40℃ | -15~+40℃ | -15~+40℃ |

| Crawler Power | 42KW(56HP) | 42KW(56HP) | 42KW(56HP) |

| Dimension: L*W*H | 7300*2380*2150mm | 7300*2380*2150mm | 7300*2380*2150mm |

| Net Weight | 7T | 7.3T | 7.5T |

5 Advantages of Crawler Wire Saw Machine

- The saw head of the crawler wire saw machine is relatively heavy. In actual construction, sometimes you don’t need to use expansion screws. You can fix the saw head by directly pressing the bottom angle, which greatly reduces the damage to concrete cutting.

- No need for a lot of cooling water. The crawler wire saw machine does not require a lot of cooling water. You only need to add cooling water to the head of the rope, and it can work for a long time.

- Low cost. The price of crawler wire saws is not high. YG can provide you with high-quality and low-cost crawler wire saw equipment.

- Easy to operate. Usually equipped with a wireless remote control device, the operator can easily set the cutting parameters to achieve automatic or semi-automatic cutting.

- Safer. Users can operate the remote control of the crawler wire saw machine to operate the movement of the wire saw. And there is no need to manually move the wire saw to the cutting site.

Application Range of Crawler Wire Saw Machine

- Mining: used for mining various mining stones, such as granite, marble, etc.

- Stone processing: in stone processing plants, used for large plate cutting, special-shaped processing, etc.

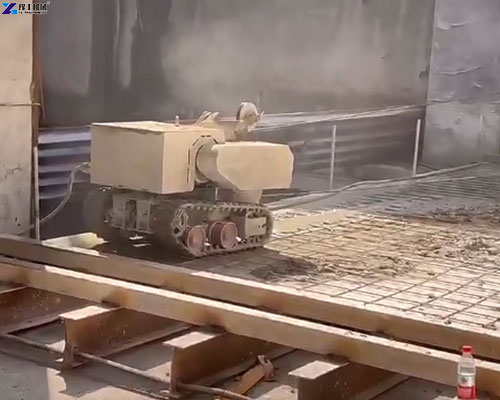

- Concrete cutting: in construction projects, used to cut various reinforced concrete support beams, bridges, beams, walls, and other structures.

- Demolition projects: in the construction projects of demolition companies and demolition companies, used to cut and demolish concrete structures, brick walls, etc.

- Other fields: crawler wire saw machines can also be used for underwater cutting operations, such as marine engineering, underwater pipeline maintenance, and other fields. In addition, it can also be used to cut some special materials, such as metals, glass, ceramics, etc.

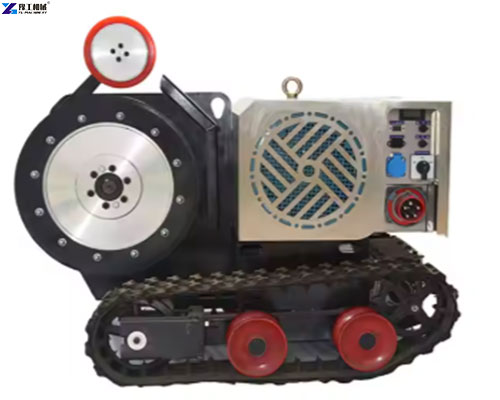

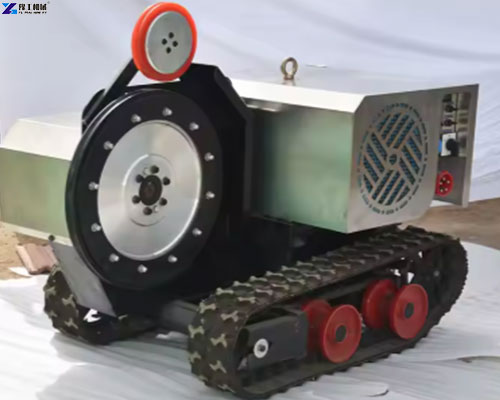

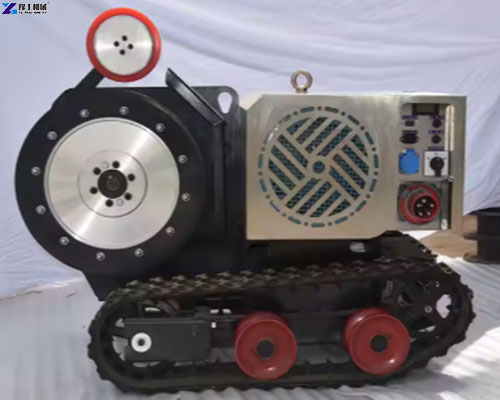

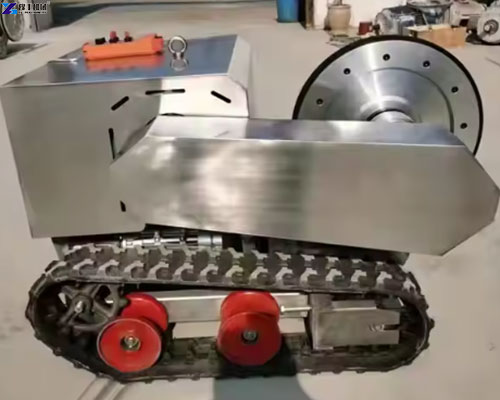

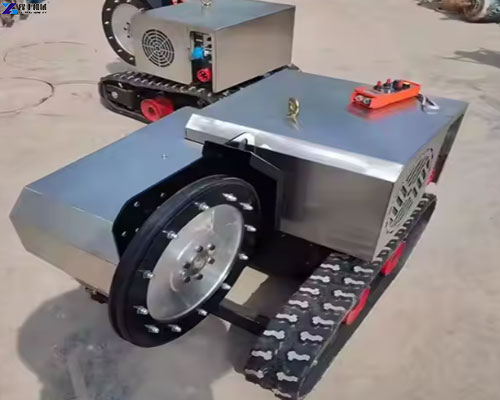

Crawler Rope Saw Machine Components

The crawler rope saw machine mainly includes a crawler a chassis, a power system, a wire saw drive device, a universal wheel, a control box, and a wire saw chain.

- Main machine: The main motor provides the rotation power required for diamond chain cutting, and the small motor provides the power required for cutting and tightening the diamond chain. The large plate drives the diamond chain to rotate.

- Double universal wheels (optional), are used to change the cutting direction.

- Control box: Control large motor, small motor, total power control, and other information display.

- Diamond cutting chain (optional) It is recommended to use the special matching diamond cutting chain provided by our company to achieve maximum economy.

- The large plate cover can prevent water, mud, and rope breakage.

Working Principle of Crawler-Type Electric Wire Saw

The working principle of the crawler wire saw is mainly based on the combination of wire saw cutting technology and the crawler mobile platform.

- Crawler mobile platform: The crawler wire saw machine adopts a crawler chassis. This design enables the equipment to maintain stable movement in complex terrain and working environments and improves the flexibility and adaptability of the operation. The crawler transmits power from the engine to the ground through the cooperation of the drive wheel and the guide wheel. Thereby generating a driving force to make the equipment move forward or backward.

- Wire saw cutting part: When the drive device is started, the cutting chain begins to rotate and circulates the flywheel and the guide wheel. While the chain rotates at high speed, it contacts the material to be cut and generates cutting force. Except for the different components that generate power, the working principle of this part is the same as that of mining wire saws, hydraulic wire saws, and high-frequency wire saws.

Crawler Wire Saw Machine Price

YG can provide crawler wire saw machines of different models. Different models have different prices. In addition, each customer has different needs and may purchase different quantities of diamond wire saws or other accessories, which also leads to different prices. The wire saw equipment provided by YG is of high quality and has a long service life, reducing your use cost from the side. We also produce small rock concrete splitters, large rock splitters, integrated drill splitters, log splitters, branch shredder machines, water drilling equipment, DTH boring machines, etc. The prices of equipment with different models and configurations will vary. No matter what equipment it is, YG will provide you with the most competitive price. You are welcome to contact us for equipment consultation!