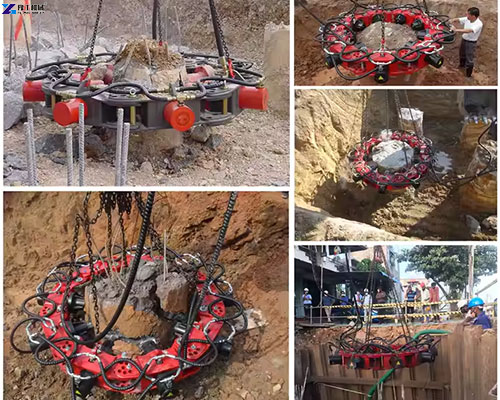

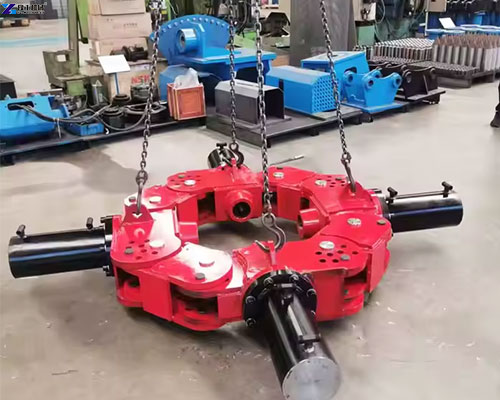

Concrete pile breaker is a kind of equipment specialized in crushing concrete piles. It is widely used in construction sites, bridge construction, dock construction, and other fields. The concrete pile breaker can quickly and accurately complete the crushing of concrete piles through efficient crushing technology. The equipment is not only suitable for concrete piles of various diameters and lengths but also can be flexibly operated in narrow or complex construction environments. Click the button below to find out the price of the concrete pile breaker now!

Concrete Pile Breaker Parameters

| Module Number | PCS | 4 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| The combination of the total weight | KG | 1600 | 2640 | 2970 | 3300 | 3630 | 3960 | 4290 | 4620 | 4950 | 5280 | 5610 | 5940 |

| Pile diameter range | mm | 400-600 | 600-800 | 800-1000 | 1000-1150 | 1150-1300 | 1300-1500 | 1500-1650 | 1650-1800 | 1800-1970 | 1970-2200 | 2200-2360 | 2360-2500 |

| Hydraulic excavator | T | 20T-30T | 30T-40T | Hydraulic system/pump station | |||||||||

| Max.Thrust | 300KN | Max.Cylinder required | 20L/min | Machinery Tonnage | ≥20T | Location pinΦ35 | |||||||

| Max.Cylinder Trip | 300mm | Chisel diameter | 110mm | Single module weight | 335KG | ||||||||

| Max.Cylinder Pressure | 300MPa | Max.Hoist Capacity | ≤500mm | Singlemodulesize | 1015*865*340mm | ||||||||

Hydraulic Pile Breaker vs. Traditional Crusher

The hydraulic pile breaker has obvious advantages compared with traditional crushers:

- Crushing efficiency: The hydraulic pile breaker utilizes a hydraulic system drive with powerful crushing capacity and precise control. The crushing efficiency is much higher than that of the traditional crusher.

- Construction accuracy: Hydraulic pile crusher can accurately control the position and strength of crushing to ensure the quality of construction, which is usually difficult to do with traditional crushers.

- Environmental impact: Hydraulic pile crusher has less noise and dust during construction, which has less impact on the environment, while traditional crusher has more noise and dust, which has more impact on the environment and workers’ health.

- Flexibility of operation: Hydraulic pile crushers can be used flexibly in narrow or complex construction environments, while traditional crusher is often restricted in construction environments.

- Maintenance cost: Hydraulic pile crusher uses advanced hydraulic systems and has lower maintenance costs, while traditional crusher has higher maintenance costs and higher failure rates.

What Factors Affect the Hydraulic Pile Breaker Price?

The price of a hydraulic pile breaker is affected by several factors, including the following:

- Brand and model: The price of different brands and models of hydraulic pile breakers varies greatly; the price of well-known brands and high-performance models is generally more expensive.

- Technical configuration: The technical configuration of the hydraulic pile crusher, such as the hydraulic system, control system, and crushing force, will affect the price. The higher the configuration, the more expensive the price usually is.

- Material and manufacturing process: The material and manufacturing process used in the hydraulic pile crusher will also affect the price. Equipment using high-strength materials and advanced technology will usually cost more.

- Market supply and demand: The supply and demand relationship in the market will also affect the price of the hydraulic pile crusher. When the demand is greater than the supply, the price tends to rise, while the price may fall when there is excess supply.

- After-sales service: Quality after-sales service usually makes the price of the equipment rise, but it can also provide users with a better experience and protection.

Maintenance and Care of Concrete Pile Crusher

To ensure the efficient operation and long-term use of concrete pile breakers, regular maintenance is essential. The following are some common maintenance and repair measures:

- Check the hydraulic system regularly: the hydraulic system is an important part of the concrete pile breaker. Check the quality and level of the hydraulic oil regularly to make sure the system can work properly.

- Clean the equipment: During construction, the concrete pile crusher will accumulate a lot of dust and debris, so it is necessary to clean the equipment regularly.

- Replace worn parts: Some wearing parts of the concrete pile crusher, such as seals and jaws, need to be checked and replaced regularly.

- Lubricate the moving parts: The moving parts of the concrete pile crusher should be lubricated regularly to reduce wear and tear and prolong the service time of the equipment.

- Check the electrical system: The electrical system of the concrete pile crusher should be checked regularly to ensure that the cable terminals and other components are intact to avoid electrical failures.

High-Quality Hydraulic Pile Cutter from YG

A concrete pile breaker is a very effective and precise construction equipment that has been widely used around the world. Whether it is a large construction project or a small construction, a concrete pile breaker can bring excellent construction results. The concrete pile breaker from YG is the first choice of many customers due to its advanced technology and high reliability. If you are looking for a high-performance hydraulic pile breaker price or a concrete pile crusher, YG’s products are the best choice. In addition, we also provide hydraulic shears, hydraulic hammers, rock saws, crushing buckets, drilling and cracking machines, and other excavator attachments.