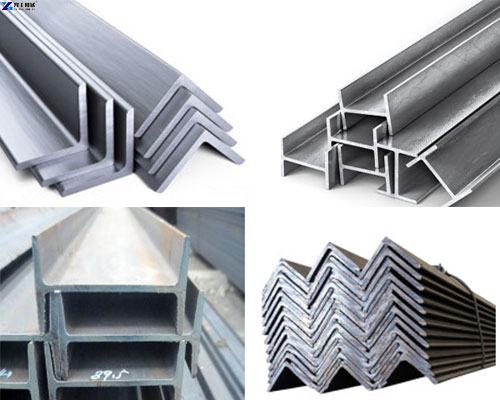

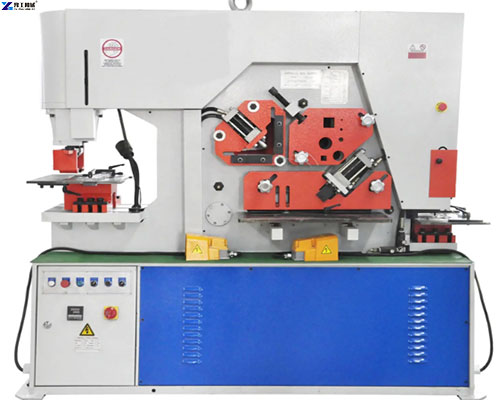

The combined punching and shearing machine is a multifunctional metal shearing, and punching equipment. This equipment can handle various steel materials such as channel steel, square steel, round steel, H steel, I-beam, and so on. It is the preferred equipment for metal processing in modern manufacturing industries, such as metallurgy, bridge, communication, electric power, etc. Punching and shearing machines have the advantages of being simple to operate, having low energy consumption, having low maintenance costs, etc. YG offers you high-quality and low-price punching and shearing machines. Click to get a free quote for the machine!

Combined Punching and Shearing Machine Parameters

| Model | Q35Y-15 | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | Q35Y-40 | Q35Y-50 | Q35-16 |

| Punching pressure(kN) | 45 | 70 | 90 | 120 | 140 | 200 | 250 | 63 |

| Max. shearing thickness(mm) | 8 | 16 | 20 | 25 | 30 | 40 | 40 | 16 |

| Strength of steel plates(n/m㎡) | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 |

| The angle of shearing(deg) | 7° | 7° | 8° | 8° | 8° | 8° | 8° | 13° |

| Shearing sizes of one stroke(w*h)(mm) | 200*15300*12 | 16*2508*400 | 20*33010*480 | 25*33016*600 | 30*35520*600 | 35*40025*700 | 40*40030*700 | 16*120 |

| Ram stroke(mm) | 60 | 80 | 80 | 80 | 80 | 100 | 100 | 26 |

| Number of strokes (times/min) | 10 | 12 | 16 | 16 | 12 | 10-20 | 10-20 | 36 |

| Depth of throat(mm) | 200 | 300 | 355 | 400 | 600 | 560 | 560 | 450 |

| Punching thickness(mm) | 15 | 16 | 20 | 25 | 26 | 35 | 35 | 16 |

| Max. Diameter of punching(mm) | 24 | 25 | 30 | 35 | 38 | 40 | 45 | 28 |

| Main motor power(kW) | 3 | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 4 |

| Dimensions of machine(L*W*H)(mm) | 1450*590*1620 | 1650*760*1780 | 1850*800*1930 | 2350*960*2100 | 2620*980*2380 | 2800*1250*2400 | 3000*1400*2400 | 1950*800*1950 |

| Machine weight(kg) | 1200 | 1600 | 2300 | 4200 | 6200 | 8600 | 11600 | 2800 |

Application of Punching and Shearing Machine

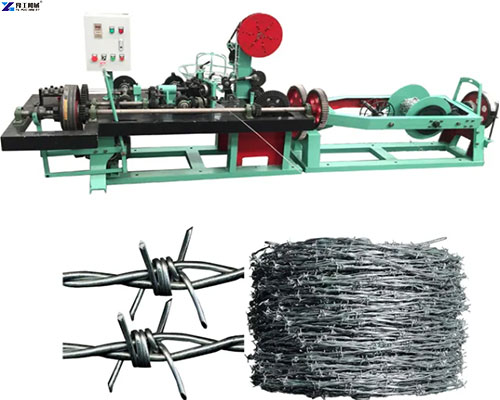

- A combined punching and shearing machine can shear round steel, angle steel, and plate. It can also punch holes, and cutouts, and is currently ideal for multi-functional shears.

- This machine can process various specific steel structures products: trailer hinges, plate hooks, inserted Zhuang, and Valon plates; agricultural threshing machine frame body; trailer bucket parts processing; high and low voltage tower parts processing; construction of embedded parts; grain and oil equipment brackets, shells, small pieces of processing; crane parts processing and so on.

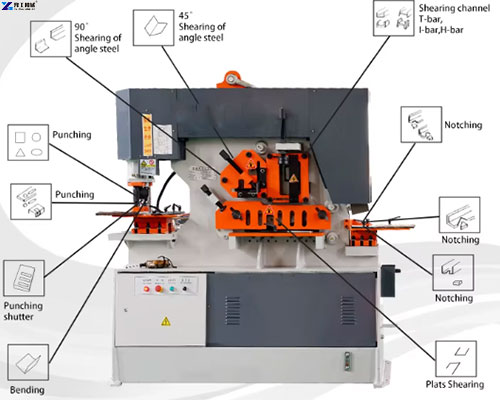

Structure of Combined punching and shearing machine

Punch Shear Machine Working Principle

The working principle of the punching and shearing machine is the main electric motor drives the punch and scissors in the machine to move, punch, and cut the workpiece. Specifically, the output of the main motor drives the flywheel and drives the gear, crankshaft, and connecting rod through the clutch to realize the linear movement of the slider. The machine then applies pressure to the material, causing it to plastically deform to achieve the desired shape and precision.

5 Characteristics of Metal Punch and Shear Machine

- The punching and shearing machine adopts hydraulic transmission, the whole machine structure is reasonable, lightweight, low noise, simple, and reliable.

- We design and assemble the machine for each station with a standard configuration.

- The machine has a good welding fit, strong and durable, has better wear resistance, and long service life. This saves economic costs from the side.

- The combined punching and shearing machine specification has five stations and a double hydraulic workstation. It can work together independently.

- The punching and shearing machine has strong versatility, and high precision, and is easy to operate. It is one of the essential equipment in the manufacturing industry.

Metal Punch and Shear Machine Molds

Punching and shearing machine dies are used in punching and shearing machines to perform process operations such as shearing, punching, and forming. These molds are usually made of high-strength, high wear-resistant alloy steel material, which is very durable and has a long service life. Depending on the different processing needs, punching and shearing machine molds come in different shapes and sizes.

Maintenance of Hydraulic Punch and Shear

- The operator should use the punching and shearing machine in strict accordance with the operation specification.

- Before each start-up, the user should add lubricating oil according to the lubrication chart. The lubricant should be clean and free of impurities.

- We must keep the equipment clean frequently. And we should paint the unpainted parts with anti-rust grease frequently.

- Users should replace and refill the lubricating oil in the machine motor bearing regularly. And often checking the motor part of the work is normal.

- The triangular belt, handle, knob, and button of the punching and shearing machine should be checked frequently to see if they are damaged. Serious wear and tear of parts should be replaced promptly.

Punching and shearing machine from YG

YG is a professional engineering equipment manufacturer, we have different models of Q35Y series combined punching and shearing machines. We can meet the needs of different customers for handling parts. Our punching and shearing machines are capable of performing efficient and precise processing operations on different types of metal sheets, tubes, and so on. We are the preferred manufacturer for many customers. Until now, customers from many countries have purchased punching and shearing machines from us, such as Malaysia, Mauritius, Saudi Arabia, and many other countries from Central Asia and South America. We also provide great rebar straightening and cutting machines, rebar upsetting machines, rebar rolling machines, CNC rebar bending machines, rebar cutting machines, rebar de-rusting machines, and other related rebar handling equipment! Click on Contact Us to get low-priced punching and shearing machines!【WhatsApp/WeChat/Skype/Phone】+86 150 3718 7716