CNC rebar bending machine is an important steel processing tool. It adopts programmed control technology and intelligent, automated control of steel hoop molding. Our stirrup bending machine has the characteristics of high speed, low power consumption, and reliable operation. It can handle all kinds of cold-rolled and hot-rolled steel bars, round steel, rebar, etc. YG also produces rebar thread rolling machines, rebar forging machines, etc. YG has advanced production equipment and rich experience and is a high-quality supplier of steel bar processing equipment. Click to get the latest price information on the equipment!

CNC Rebar Bending Machine Parameters

| Model | YG-2 | YG-1 |

| Single wire(mm) | Round steel 4-12mm, Deformed steel bar 4-10mm | Round steel 4-10mm, Deformed steel bar 4-8mm |

| Double wire(mm) | Round steel 4-8mm, Deformed steel bar4-8mm | Round steel 4-6mm, Deformed steel bar 4-6mm |

| Max bending angle | ±180° | ±180° |

| Center pin diameter | 16、18、20 | 16、18、20 |

| Maximum towing speed | 60m/min | 60m/min |

| Maximum bending speed | 800°/sec | 800°/sec |

| Machine size | 3280*1000*1700mm | 2600*800*1700mm |

| Device color | Yellow(customized) | Yellow(customized) |

| Pieces Processed | ≤2 | ≤2 |

| Air circuit system pressure | ≥0.8mpa | ≥0.8mpa |

| Total Power | 20kw | 14kw |

| Working temperature | -5°C~40° | -5°C~40° |

| Length accuracy | ±1mm | ±1mm |

| Angle accuracy | ±1° | ±1° |

| Average power | 5KW/h | 4.5KW/h |

| Total weight | 1350KG | 1150KG |

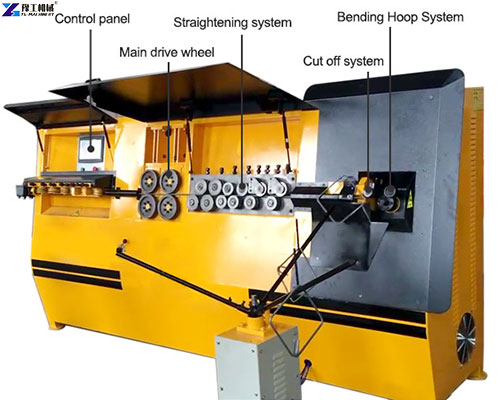

CNC Stirrup Bending Machine Structure

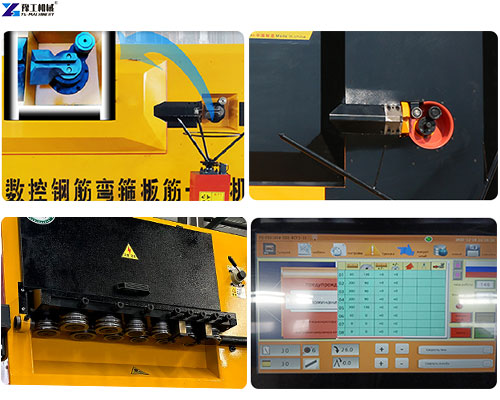

CNC rebar bending machine mainly includes a machine shell, straightening mechanism, compression traction mechanism, bending and forming mechanism, shear mechanism, hydraulic pump station, electronic control cabinet, control platform, and other parts. The machine consists of two sets of horizontal and vertical automatically adjustable straightening wheels, combined with four traction wheels, driven by servo motors. So it can make the steel bar bending angle more precise.

CNC Bar Bending Machine Application scope

The hoop bar is an indispensable steel component in the beams and columns of buildings. Therefore, we usually use the CNC rebar bending machine in housing projects, bridge projects, highways, railroads, bridges, tunnels, airports, water conservancy projects, ports and bridges, and other types of construction projects, such as steel bending processing. It serves as an advanced processing equipment with high efficiency and uniform workpiece standards.

5 Advantages of Automatic Rebar Bending Machine

- The automatic rebar bending machine contains two sets of automatically adjustable straightening wheels, four traction wheels, and an imported servo motor drive. This ensures straighten the steel bars to the best precision.

- Control system. The machine adopts a foreign mature control system. The control system has fault identification and alarm function.

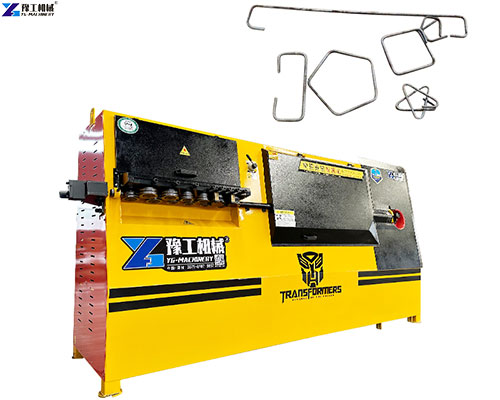

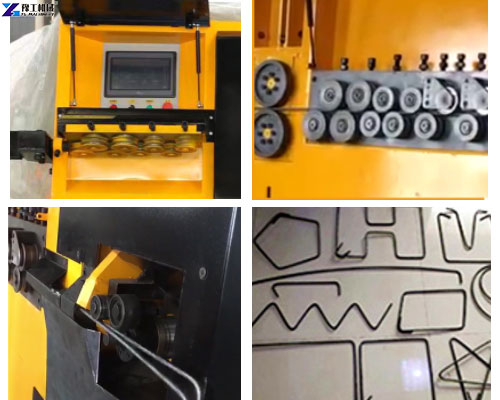

- Various shapes can be made. This machine can make up to 60 shapes within the bending angle. At the same time can store a variety of different product shapes, and has a storage graphics library. For example, the shape of hoop bars, plate bars, horseshoe bars, eight-bar, and so on.

- More intelligent. It can continuously produce a variety of shapes without the machine being adjusted.

- Simple operation. Only one person is ok during the working process of the machine, the whole process is simple and labor-saving, and the speed is adjustable.

CNC Steel Bending Machine Working Principle

The working principle of the CNC steel bending machine is that the pulley and spur gear decelerate the motor. At the same time, it drives the eccentric disk rotation after the eccentric disk through the eccentric hinge driving two rods. At the same time, each connecting rod is connected to a rack, so that the rack in the slide for reciprocating motion. The movement of the racks further drives the gears, causing the disk to reciprocate within a certain angle. At the same time, the shaft hole on the working plate will insert the corresponding shaft, when the working plate rotates, these shafts will also rotate, so as to realize the bending of the steel bar.

Maintenance of Automatic Rebar Bending Machine

- First, check whether the air filter and pressure regulator valve failed.

- Clear the control electrical cabinet and operating table these control components are on the dust.

- Inspect the fastening of each part of the connecting bolts, if necessary, tighten them with special tools.

- To check whether the proximity switch is working properly.

- View whether the cable insulation is damaged.

- Check the protective grounding wire.

- Review whether there is any air leakage in the air pipe joints and air channels.

- Check the wear and tear of the relevant motor braking system including spring, spring tensioning, solenoid, moving brake, brake disk, and motor.

CNC Rebar Bending Machine from YG

We offer powerful CNC rebar bending machines that can realize automatic straightening, bending, and cutting of steel bars with one machine. CNC steel bar bending machine is suitable for cold rolled ribbed steel bars, hot rolled grade steel, cold rolled round steel, and hot rolled coil steel hook bending. Therefore, it has a wide range of applications. In order to help people in the field of construction engineering and other areas of better handling of steel bars. We also produce rebar straightening and cutting machines, rebar hoop bending machines, and rebar cutting machines. And here are also other steel bar machines: steel bar thickening machines, steel bar thread rolling machines, steel bar rust removal machines and chain link fence machines. If you need, please contact us for equipment information. We offer you a competitive price!

YG’s other rebar processing-related equipment

YG’s rebar processing equipment covers almost all aspects of rebar processing. In addition to rebar straightening, bending, and cutting equipment. We also produce other rebar machinery: rebar forging machines, rebar thread rolling machines, rebar rust removal machines, and chain link fence machines. This equipment helps users solve various problems faced when using rebar. Tell us your needs, we will provide you with professional rebar equipment solutions!