The barbed wire making machine specializes in producing various sizes of barbed wire. It can produce all kinds of multi-strand wire barbed wire. The finished products produced by this machine can be applied in national defense, railroad, highway, agriculture, and animal husbandry scenarios. This equipment is powerful, easy to operate, and widely applicable. YG can offer you single-strand barbed wire machines, double-strand barbed wire machines, and forward and reverse twisted wire barbed wire machines. Click to get a quote for your barbed wire machine!

Barbed Wire Making Machine Technical Parameters

| Raw material | hot plate low carbon wire, galvanized wire |

| Tearing distance | as required |

| Strand diameter | 1.6-2.6mm |

| Wire diameter | 1.6-2.2mm |

| Theoretical output | 50-60kg/h |

| Motor | 2.2kw |

| Main drive shaft speed | 357 rpm |

| Production | 70 kg/h |

| Weight | 1200 kg |

| Main part size | 1900mm * 1300mm * 980mm |

| Dimensions of twisted parts | 1300mm * 800mm * 700mm |

| Damage-prone parts | Twist, cutter |

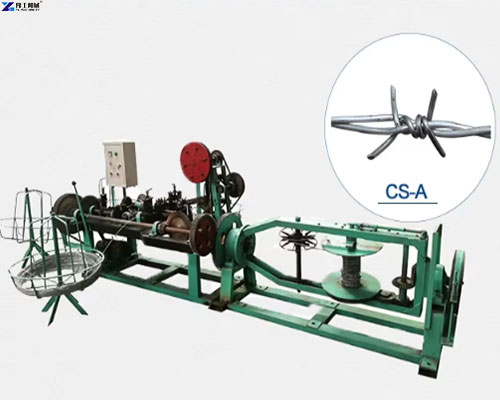

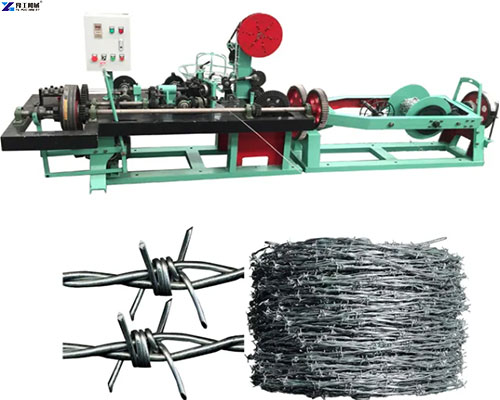

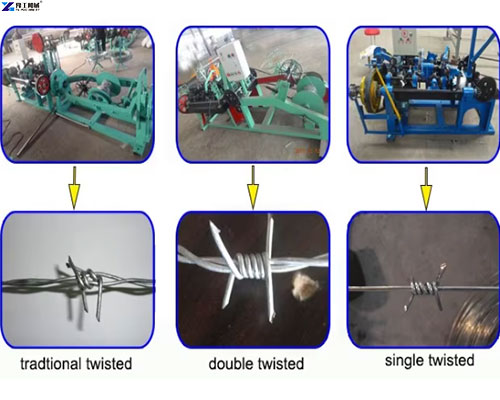

Different Types of Barbed Wire Manufacturing Machines

- Single-strand wire-making machine. This equipment has two parts: winding and winding. It is also equipped with three wire-releasing disks. The machine runs smoothly and has high production efficiency and advanced electronic counting control.

- Double-strand wire machine. This machine has two parts: winding and twisting. There are four payoff disks. All parts of the machine work harmoniously and operate flexibly and reliably.

- Forward and reverse twisting wire mesh machine. It consists of positive and negative twisting, winding, and friction rope collection in two parts. There are also four reels. This equipment is characterized by easy operation, low noise, and energy saving.

Application of Automatic Wire Fence Machine

The finished products produced by the wire making machine have high strength, corrosion resistance, and toughness. People widely use the barbed wire machine in the fields of national defense, railroad, highway, agriculture, and animal husbandry. Specific application scenarios are military heavy land, prisons, government agencies, banks; living community fences, private homes, villas, fences, doors and windows, highways, railroad guardrails, and border lines and other protection.

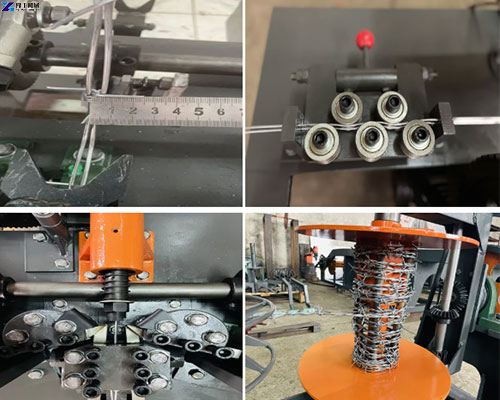

Machine’s Structure

It consists of two parts which are connected with winding and twisting, and is equipped with four feeding spools, and all parts of the machine are coordinated with each other, and the action is horizontal. The machine is mainly suitable for producing various kinds of multi-strand barbed wire. The materials used should meet the requirements of stable, flexible, and reliable operation.

Features of Barbed Wire Making Machine

- Compact structure. The size of the machine is relatively small, which is conducive to saving space, and at the same time, it is easy to transport and install.

- Easy to operate. The wire manufacturing machine is equipped with an easy-to-operate control system. Users can start using it immediately, saving the time and cost of learning to operate it.

- Low energy consumption. The wire-making machine consumes less energy during operation, which is conducive to reducing production costs and improving economic efficiency. At the same time, low energy consumption also meets the requirements of modern industry for environmental protection and energy saving.

- Produce good quality. The quality of the products produced by the wire machine is stable and reliable and meets the relevant standards and requirements. This ensures the reliability and durability of the barbed wire products in various application scenarios.

- High safety. The machine adopts advanced electronic counting control and other safety measures, which can ensure the safety of operators in the production process.

YG Offers High Speed Barbed Wire Machine

YG Machinery has advanced production and manufacturing equipment and technology, a sound quality assurance system, a good reputation, and has received the trust of domestic and foreign customers. Our equipment and finished barbed wire products have been exported to Southeast Asia, the Middle East, the United States, Japan, Africa, Europe, and other countries and regions. We also supply fencing wire making machines, rebar straightening and cutting machines, rebar bending machines, rebar cutting machines, rebar descaling machines, punching and shearing machines, rebar forging machines, rebar rolling machine, and other equipment. Click to get the factory price for the barbed wire machine!