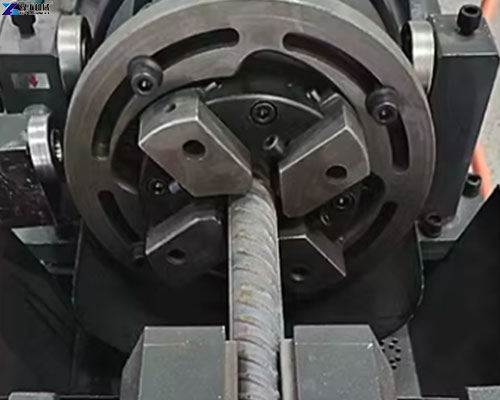

The bar threading machine utilizes the principle of roller rotation extrusion to process the end of the rebar into a straight thread that meets the standard requirements. The machine can process rebar of different specifications. The processed rebar head has high connection strength and reliable connection. The rebar rolling machine is an important rebar processing equipment in construction, bridges, roads, and other projects. Click to get the factory price of the machine!

Bar Threading Machine Parameters

| Model | YG28-40 | YG28-80 | YG28-150 | YG28-185 | YG28-200 |

| Max rolling pressure | 120KN | 150kn | 150kn | 180kn | 200kn |

| Hydraulic diameter | 5-36MM | 6-42mm | 6-48 | 10-60mm | 14-80mm |

| Rolling wheel diameter | 120-170MM | 120-170mm | 120-170mm | 175-220mm | 175-220mm |

| Max width of rolling wheel | 110MM | 110MM | 110MM | 150mm | 150mm |

| Spindle center distance | 120MM | 120MM | 120MM | 150-300mm | 150-300mm |

| Rolling wheel aperture | 54hole | 54hole | 54hole | 75hole | 75hole |

| Hydraulic power | 4kw | 2.2kw | 2.2kw | 3kw | 5.5kw |

| Main motivation | 4kw | 5.5kw | 7.5kw | 11kw | 11kw |

| Spindle speed | 36-78/min | 36-78/min | 36-78/min | 20-64/min | 20-64/min |

| Spindle tilt angle | ±5° | ±5° | ±5° | ±10° | ±10° |

| Thread length | No limited | No limited | No limited | No limited | No limited |

| Dimensions | 1.4*1.2*1.4m | 1.48*1.33*1.44m | 1.47*1.33*1.44m | 1.78*1.73*1.43m | 1.78*1.73*1.43m |

| Weight | 1100kg | 1700kg | 1800kg | 2000kg | 2600kg |

7 Characteristics of Coupler Threading Machine

- After the bar threading machine processing steel bar thread tooth type precision is very high, and the diameter of the same size.

- Its structure is compact, simple to operate, and has thread processing speed.

- As long as a rebar loading can complete the processing of thread, the processing efficiency of the head is very high.

- The equipment has a high degree of automation, and can automatically raise the knife, and automatically return it.

- The quality of the joints processed by the rebar rolling machine is stable and reliable. The strength of the joint is higher than the usual parent material.

- It processes a wider range of rebar types and takes up less equipment.

- Bar threading machine has a long service life of the rolling wheel, which saves the cost of replacing the rolling wheel.

The Role of Thread Rolling Machine for Sale

- It solves the problem of pre-processing the end of the steel bar.

- This machine reduces the processing procedures and multiple steel handling and improves the efficiency of on-site production and processing.

- The bar threading machine can realize the rolling processing of multiple specifications of steel bars by using one rolling head. This solves the situation that one rolling head is needed for each specification to process straight threads on the end of the rebar.

- The wire rolling machine adopts internal cooling liquid, which solves the problem of chip removal during rolling processing.

- The machine has high automation strength, feeding and resetting will stop automatically. It improves the efficiency of steel wire rolling.

YG’s Steel Bar Thread Rolling Machine

One bar threading machine produced by YG can handle different specifications of rebar. It can handle most specifications of rebar. You can also use a rebar dunnage machine to dunnage the rebar before wire rolling. We also provide rebar straightening and cutting machines, rebar bending machines, rebar cutting machines, rebar upsetting machines, CNC rebar bending machines, rebar rust removers, chain link fencing machines, and so on. We give you a series of solutions for rebar processing. Click contact us to get a free quote!