An automatic paper cup machine can process raw paper into paper containers. The cups can hold ice cream, jam, butter, drinks, etc. Paper cups for hot drinks can withstand temperatures above 90℃. With the characteristics of safety and hygiene, light and convenience, he is the most used cup in public places, hotels, and restaurants. Click to get more information about the paper cup machine!

Automatic Paper Cup Machine Parameters

| Model | YG-M100 |

| Paper Cup Size | 3-16 OZ |

| Raw Material | One-side or two-side PE coated paper(Singe PE or Double PE coated paper) |

| Speed | 80-100pcs/min |

| Suitable paper weight | 160-260g/㎡;±20g/㎡ |

| Voltage supply | 380V(220V) 50HZ |

| cup size | bottom28-54mm,top40-75mm,high30-95mm |

| Working Air Source | 0.4-0.6Mpa; 0.4m³/min |

| General power | 4.5kw |

| Net weight | 1500kg |

| Cup Side Sealing | Ultrasonic |

| Bottom Knurling | HOT AIR SYSTEM |

| We can customize the machine and mold according to the customer’s requirements!!! | |

Application of High Speed Paper Cup Machine

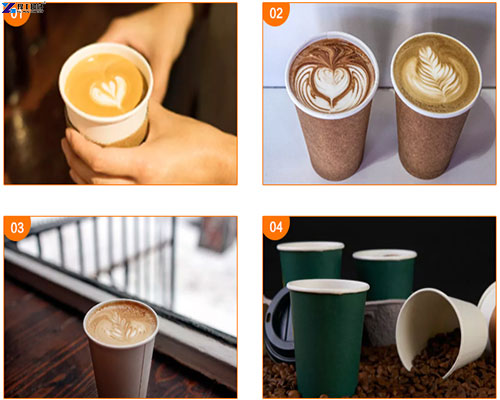

- There are various paper cups, such as beverage paper cups, tea paper cups, coffee paper cups, advertising and market paper cups, ice cream paper cups, or other disposable cone-shaped food paper containers.

- Application areas: The application mainly concentrates on disposable consumer goods such as catering, beverages, supermarkets, and so on. People use paper cups widely in fast food restaurants, beverage stores, coffee shops, and other places.

Paper Cups That Cup Forming Machine Produced

Cup material: single-side PE lamination paper cups, double-side PE lamination paper cups.

Paper cup size: 3~16 ounce size cups. We can also customize it according to your needs.

6 Features of Disposable Paper Cup Making Machine

- The automatic paper cup machine produced by YG adopts imported main materials and bearings. The torque is wear-resistant and adapts to long-time high-speed operation.

- The high-speed paper cup machine is equipped with an imported motor frequency converter and electrical control components. Computer program control frequency converter, stepless speed regulation.

- The paper cup machine is specially designed with photoelectric detection and fault alarm function.

- The whole cup-forming machine has stable electrical performance, and long service life, and can adapt to the conditions of unstable voltage.

- The key parts of the machine, such as the gearbox, transmission shaft, clutch mold, control system, etc., have the characteristics of trouble-free and maintenance-free.

- Adopting high-quality stainless steel table shell and parts, clean and sanitary, anti-pollution, and wear-resistant.

Workflow of Paper Cup Making Machine

A disposable paper cup molding machine is a kind of multi-station automatic molding machine. Its workflow is mainly a continuous process of automatic paper feeding, sealing, oil filling, bottom punching, heating, knurling, and unloading cup collection. The automatic paper cup machine also has photoelectric detection, fault alarms, counting, and other functions. Paper cups produced

Automatic Paper Cup Machine Supplied By YG

YG specializes in providing efficient and reliable automatic paper cup machines. We have rich production experience and advanced technical strength.YG produces a wide range of paper cup machine types and specifications to meet the needs of different customers. We also produce paper napkin machines and toilet paper machines. Paper cup machines are easy to operate, have stable performance, small area, and have high benefits, which is the first choice project for investment and business. Click to get the latest equipment offer!