An auto drilling and tapping machine is a specialized equipment for metal processing. The machine’s main function is to process internal threads for metal workpieces. It uses a rapidly rotating tap to make contact with the workpiece, enabling the creation of threaded holes efficiently and accurately. Tapping machines are widely used in the automotive and machinery manufacturing industries. They are capable of completing threading jobs of high quality and quantity. Click on the button to get a quote for tapping machines!

Auto Drilling and Tapping Machine Parameters

| SPECIFICATION | YG-20/40 | YG-25/50 | YG-30/60 |

| TAPPING CAPACITY IN STEEL | 6-20mm coarse pitch, 6-40mm fine pitch | 6-25mm coarse pitch, 6-50mm fine pitch | 10-30mm coarse pitch, 10-60mm fine pitch |

| SPINDLE DIAMETER | 30mm | 35mm | 40mm |

| SPINDLE TRAVEL MAX. | 110mm | 110mm | 125mm |

| COLUMN DIAMETER | 100mm | 100mm | 110mm |

| DISTANCE B/W SPINDLE CENTER TO COLUMN | 216mm | 216mm | 250mm |

| TABLE SHAPE | Rectangular | Rectangular | Square |

| TABLE SIZE (LxB) | 405x225mm | 405x225mm | 760x590mm |

| WORKING AREA | 330x150mm | 330x150mm | 620x260mm |

| FLOOR AREA(LxB) | 1220x760mm | 1220x760mm | 1400×620 |

| NO. OF SPEEDS | 2 AC Drive Optional | 2 AC Drive Optional | AC Driver |

| MOTOR REQUIRED | 2 HP/1440 rpm | 2 HP/1440 rpm Or 2 HP/900rpm | 3 HP/1440 rpm |

| TOTAL HEIGHT | 1900mm | 1900mm | 2100mm |

| TOTAL WEIGHT | 350kg.(approx) | 400kg.(approx) | 550kg.(approx) |

| MAX. TAP SHANK THAT CAN BE BEHOLD IN THE TAP HOLDER | 20mm | 30mm | 40mm |

| COMPLETE BELT COVER | YES | YES | YES |

| MOTOR COVER WITHIN MACHINE FRAME | YES | YES | YES |

| COOLANT SYSTEM | YES | YES | YES |

| COUNTER METER | YES | YES | YES |

| SAFETY CUT-OFF LIMIT SWITCHES | YES | YES | YES |

| PHASE PREVENTER | YES | YES | YES |

| COOLANT TANK CAPACITY | 40 Liters | 40 Liters | 40 Liters |

| VARIOUS PITCH SIZES CAN BE DONE | METRIC PITCH 0.8,1.0,1.25,1.5,1.75, 2.0,2.5 UNIFIED PITCH(tpi) 26,24,20,19,18,16,14 12 | METRIC PITCH 1.0,1.25,1.5,1.75, 2.0,2.5,3.0,3.5 UNIFIED PITCH(tpi) 24,20,19,18,16,14 12,11 | METRIC PITCH 1.0,1.25,1.5,1.75, 2.0,2.5,3.0,3.5,4.0 UNIFIED PITCH(tpi) 24,20,19,18,16,14 12,11,10,8 |

| STANDARD EQUIPMENT | Floating Tap holder 2no., 2no. Tap collets of any size, 2no. Lead Screw (Fitted), spanners, LN keys | Floating Tap holder 2no., 2no. Tap collets of any size, 2no. Lead Screw (Fitted), spanners, LN keys | Floating Tap holder 2no., 2no. Tap collets of any size, 2no. Lead Screw (Fitted), spanners, LN keys |

Application Range of Auto Tapper Machine

- Machine housings: auto-drilling and tapping machines can produce internal threads on machine housings of different sizes. These threads are used for connection, fixing, and other needs.

- Equipment ports often require threaded holes to connect to other components.

- Nuts and flanges: these components often have multiple threaded holes. A tapping machine ensures that the location and accuracy of each threaded hole meet standards.

- Automotive parts: many threaded connections are required on parts like bodies, frames, chassis, connecting rods, and engines. Therefore, tapping machines are needed to make high-precision threads.

- Electronic components: in producing electronic products, circuit boards and other electronic components also need to be processed by tapping machines.

5 Features of CNC Drilling and Tapping Machine

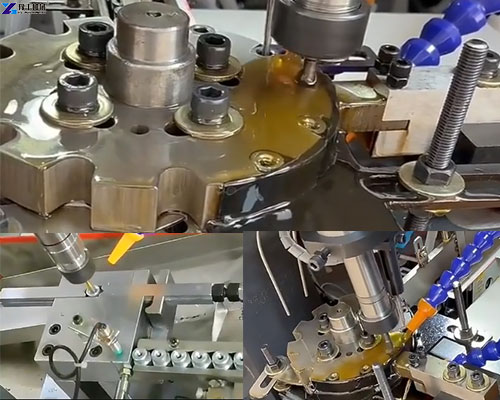

- High working efficiency: the auto tapper machine can realize high-speed continuous cycle operation. The special motor is durable, a high degree of automation. And one person can operate many sets of equipment at the same time, which significantly saves labor costs.

- Good working effect and high accuracy: the threads tapped by the tapping machine have high accuracy and can be detected by dental gauge. It is suitable for processing soft materials such as thin plates, light alloys, and synthetic resins.

- The tapping machine is very safe to use: the auto drilling and tapping machine is equipped with a safe torque clamping cylinder, which ensures less damage to the tap and reduces the risk during operation.

- Flexibility in use: the tapping machine is easy to operate. Can be configured with a multi-axis device for multi-axis synchronous processing, and production efficiency is greatly improved.

- Wide applicability: the tapping machine is suitable for all machinery manufacturing industries, such as machine tools, mold machinery, plastic machinery, printing machinery, packaging machinery manufacturing plants, engineering machinery, and automotive and motorcycle parts.

Precautions When Using an Automatic Tapping Machine

- Before using the auto drilling and tapping machine, the bottom hole of the thread should be chamfered.

- When using the equipment, the positioning of the workpiece should be accurate, and the tap axis should be perpendicular to the surface of the workpiece.

- Adjust the tap position before tapping, no more pressure after cutting in 3-4 turns.

- When tapping it is recommended to use intermittent mode, every 3 turns to reverse 1 turn chip removal.

- CNC drilling and tapping machine tapping blind holes regularly back tap, clean up the hole chips.

- When tapping screw holes in plastic materials, it is necessary to add lubricating coolant, different materials, and different fluids.

- After using the tapping machine, clean up the tap for the next use.

Auto Drilling and Tapping Machine from YG

YG’s tapping machine adopts advanced cutting technology and a precise control system, which can efficiently and accurately process various specifications of internal threads. YG’s tapping machine is reasonable in design, stable in structure, simple in operation, and high in safety. It can be adapted to the processing of workpieces of many different materials and specifications. YG also provides steel bar straightening and cutting machines, steel bar bending machines, steel bar dunnage machines, steel bar thread rolling machines, and other related products. Contact us to get the factory price of the tapping machine!