Rock splitter for excavator is a rock splitting equipment based on excavator power machinery. It uses the hydraulic power of the excavator itself to install the large splitter directly on the excavator’s arm, and the working efficiency is more than 10 times higher than that of the handheld hydraulic splitter. This machine is particularly suitable for non-blasting large-volume rock excavation and ore mining. Such as urban building foundations, rock excavation, rock excavation for the construction or expansion of high-belt highways, etc. Please contact us for more detailed information!

Parameters of Rock Splitter For Excavator

| Model | YGM-S200 | YGM-S280 |

| Splitting Force(ton) | 3800 | 5700 |

| Piston Diameter(mm) | 200 | 250 |

| Required Drilling Diameter(mm) | 90-110 | 110-130 |

| Required Drilling Depth(mm) | 1600 | 1700 |

| Crack Width(mm) | 32 | 35 |

| Drilling Gap Distance(mm) | 1000-1500 | 2000-2500 |

| Splitting Speed(s) | 40-50 | 40-50 |

| Required Pressure(mpa.) | 60-80 | 80 |

| Splitting Gun Length(mm) | 2700 | 2800 |

| Weight(kg) | 900 | 1000 |

5 Features of Hydraulic Rock Splitters

- More effective demolition of rock concrete, avoiding vibration, noise, and dust generated by traditional blasting.

- Increase environmental protection, reduce material costs, and reduce material loss.

- The rock splitters for excavators adopt an all-steel structure with high strength and stronger adaptability to the work site, so it can operate normally in most sites and is economical and applicable.

- In the overall rock fracture, it can replace the breaker, and its power is 5 to 10 times that of the breaker.

- The hydraulic rock splitters have high production efficiency and the operation process is stable and smooth.

Application Fields of Rock Splitter For Excavator

- It can be used for open excavation, underground excavation, ditches, construction, and other rock excavation in tunnel shafts and tunnels (subways, highways, railways, etc.).

- It is suitable for mining in open-air scenes, large rocks, mines, etc.

- Splitting of various rocks such as granite, marble, sandstone, limestone, etc.

- Mining of metal mines, non-metallic mines, and coal mines.

- Hydraulic Large rock splitter can also handle large waste rocks, dead corners, leveling sites, etc.

- In water conservancy projects, large hydraulic splitters can be used to handle rocks on riverbeds or riverbanks. Obstacles in the river channel can be removed to improve the navigation capacity and flood control capacity of the river channel.

Large Rock Splitter Functional Principle

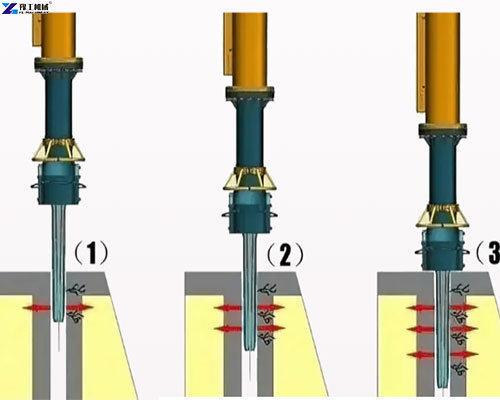

Rock splitter for excavator cleverly uses the power of ultra-high pressure oil. After this high-pressure oil is strongly output from the hydraulic power station, it will be strengthened by a supercharger to further increase its energy. Subsequently, this enhanced force drives the oil cylinder inside the splitting rod, generating amazing thrust. This thrust pushes the hydraulic top in the splitting rod to expand outward, “bursting” the rock from the inside. At the same time, the direction of the splitting can be preset completely according to our wishes, ensuring that the rock can be split along the predetermined path, thereby achieving efficient and accurate crushing and excavation effects.

How To Operate A Big Hydraulic Rock Splitter?

- Use equipment such as air guns or hydraulic rock drills to set splitting points and drill holes in the rock or concrete to be removed. To reduce the working resistance of the splitter.

- Apply grease evenly on the contact surface of the splitting and wedge of the splitter, and turn the manual valve on the power station to the working gear I# or II#.

- Turn on the power station. At the same time, open all manual valves on the splitter to the working gear I# or II# to determine the running direction of the splitter wedge.

- Open the working gear of the manual valve and insert the rock splitter for the excavator into the hole of the rock or concrete.

Start splitting

a. The splitting section of a single gun can reach more than 1 square meter. The more fragile the tensile strength,

b. The harder the rock. The better the splitting effect.

c. Each splitting time is 8-15 seconds.

Why Choose YG’s Excavator Mounted Hydraulic Rock Splitter?

Relying on its strong comprehensive strength and excellent scientific research team, YG continues to innovate and launches a series of new generation splitter products with excellent performance, which has rapidly emerged as the core equipment in the field of mining and stone engineering. In addition to rock splitter for excavators, we also produce hydraulic diamond wire saws, concrete wall saws, water drilling equipment, DTH boring machines, hydraulic pile driver machines, and various drilling equipment. These equipments are made of high-quality raw materials and reasonable structures, with simple operation and long service life. In addition to providing customers with high-quality equipment, we also provide customers with comprehensive services. Our sales manager will actively answer any questions from customers and recommend reasonable equipment models according to customer needs. In addition, we will also provide a one-year warranty. Customers can contact us if they have any questions within one year of receiving the large splitter!