The rebar coupler machine is excellent equipment for connecting rebar. This equipment can quickly complete the rebar connection work through the sleeve. It adopts hydraulic pressure to carry out the work, with a large connecting force and good connecting effect. The machine is easy to operate and more durable. A rebar cold extrusion machine is a popular equipment for connecting rebar. A customer from UAE ordered one rebar cold extrusion machine and 5000 threaded rebar couplers from us last month. Click get a free quote now!

Rebar Coupler Machine Technical Parameters

| Model | YGJY-32 |

| Applicable rebar size | Φ16-Φ32mm |

| Working stroke | 45mm |

| Pressure | 63Mpa |

| Motor power | 4kw/380v |

| Weight | 120kg |

| Oil pump size | 800*600*800mm |

| Squeeze clamp size | 500*170*200mm |

5 Advantages of Rebar Extrusion Press Machine

- The construction process of the rebar coupler machine is simple and easy to operate.

- The construction of the machine is fast, and it can save a lot of time compared with the traditional welding method.

- It is suitable for the radial extrusion connection of ribbed steel bars with diameters φ16-φ40 in reinforced concrete structures.

- This technology has the advantages of stable and reliable joint quality and no environmental influence compared with the traditional lap and welding technology.

- The connection speed of the rebar cold extruder is fast, lightweight, easy to move, and simple to operate.

Steel Cold Extrusion Machine Operation Precautions

When the rebar coupler machine is working, it generally works two times. Firstly, half of the sleeve is put into a steel bar, half of the joint, and then the other half of the joint.

- We should mark the rebar with a line so that we can ensure the insertion depth. The end of the rebar should not be more than 10mm from the midpoint of the sleeve length.

- The axis of the connecting rebar and the rebar sleeve should be on the same axis without offsetting and bending.

- Should be crimped from the center of the reinforcement sleeve to the end buckle by buckle, and the pressure mold should be aligned with the same indentation position mark.

- It is advisable to pressurize the connection to the specified working pressure and ensure that the load is removed for 2 seconds.

- Measure the extension length of the sleeve after crimping, and make a good record of the connection operation.

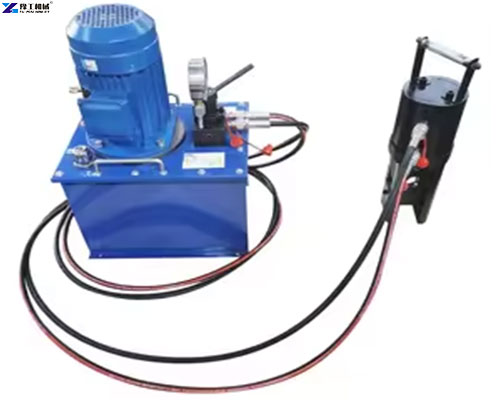

Steel Rebar Coupler Machine from YG Equipment

The cold extrusion machine for steel bars provided by YG is equipped with advanced components. Such as an electric ultra-high pressure hydraulic station and ultra-high pressure manual reversing valve. We also improve the design of other parts of the machine. The rebar coupler machine is easier to operate and more durable at the same time. The rebar cold extrusion machine is responsible for completing the extrusion connection of the steel bar. You can also buy a rebar forging machine, or a rebar thread rolling machine to first process the end of the rebar into a part that can be connected with a sleeve. And then start the connection work. We also provide high-quality rebar bending machines, rebar cutting machines, CNC rebar bending machines, rebar rust-removing machines, and so on. Send us your requirements and we will offer you the most competitive factory price!