Good news! The toilet paper rewinding machine, tissue paper cutting machine, and tissue packaging machine have been successfully sold to Saudi Arabia! The successful cooperation between YG and our Saudi Arabian customer shows that our equipment’s popularity has increased. We will continue to work hard to study the demand for toilet paper machines in different countries and help more customers get their satisfactory toilet paper production machinery. Click to get a free equipment quote!

Toilet Paper Rewinding Machine Purchased by the Customer

Our customer purchased a semi-automatic toilet paper production line. The production line mainly includes a YG-1880 toilet paper rewinding machine, manual band saw paper cutter and pneumatic water-cooled sealer. The cutting and sealing part needs to be done manually. The specific machine parameters are as follows:

YG-1880 Toilet Paper Rewinding Machine

Base paper width: 2200mm

Original paper outer diameter: 1100mm

Inner diameter of base paper core: 76.2mm

Finished product diameter: 60-120mm

The inner diameter of the paper core of the product: is 20-50mm

Programming controller: PLC computer programming

Processing capacity: 180 m/min

Punching pitch: 90—180mm

Paper ejection rack: 1-3 layers can choose

Power: 5.5kw

Machine weight: 3000kg

Machine size: 6200x3000x1800mm

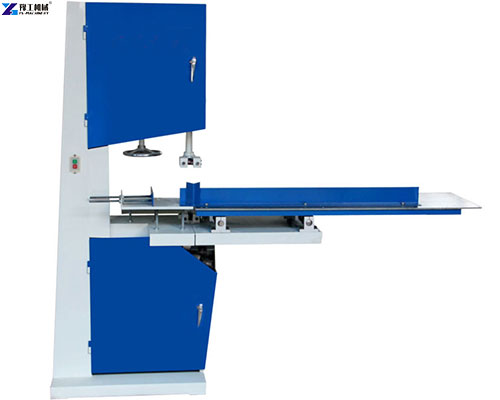

Tissue Paper Cutting Machine Parameters

Finished product specifications: adjustable cutting length

Processing capacity: 1.5 tons/day

Saw blade length: 3750mm

Required power: 1.1kw

Machine weight: 460kg

Host size: 1300×80×1800mm

Pneumatic Water-Cooled Sealer

Power supply voltage: 220V/50HZ

Sealing width: 420mm

Flat heating wire width: 6mm

Diameter of round heating wire: 0.5mm

Machine weight: 40kg

Host size: 750x700x800mm

5 Advantages of Paper Slitter Rewinder Machine

- The toilet paper rewinding machine can be fully automatic for trimming, spraying glue, sealing the mouth, pumping the shaft, and other actions in the same process. The work is efficient, precise, and stable.

- The whole machine’s pneumatic belt feeding, rewinding axis, and each axis of the original paper have a separate tension adjustment mechanism.

- The rewinding, unwinding, and traction belt of the toilet paper rewinder are all driven by frequency conversion technology.

- The structure of the machine is compact and the actual operation is convenient.

- The machine can enhance the softness and toughness of the paper by embossing, gluing, and laminating, making the finished products more comfortable to use.

About YG’s Paper Roll Slitting Rewinding Machine Customers

At present, our tissue-related equipment has been sold to South Africa, Kuwait, Lebanon, Libya, Turkey, Canada, Australia, Spain, Kyrgyzstan, Kazakhstan, and Azerbaijan! We have also received positive feedback from our customers. They said, “The machine works very stably and there has been no problem until now”. We can also provide you with an automatic toilet paper production line, paper napkin making machine, paper bag making machines, paper cup making machines, roll die cutting machines, hamburger box making machines, and related supporting equipment. So that you can process large rolls of paper into packaged rolls, napkins, and draws. Click to get our latest quotation!